Posted by Chrom Tech on 20th Nov 2025

How to Choose the Right Septa for Your Autosampler Vial Closure

When performing LC (Liquid Chromatography) or GC (Gas Chromatography) analyses, it’s important to store and transport samples in the right type of vial. Chromatography vials come in a variety of shapes, sizes, and closure styles—each designed for specific applications. If you’re unsure where to start, our autosampler vial selection guide covers vial types in detail. In this article, we’ll focus on another critical factor: the septa material used in vial caps, which directly impacts sealing integrity, compatibility, and background noise in your analysis.

Common Septa for LC Vials

In liquid chromatography, screw thread vials and closures are most commonly used. The standard septa material for these is a PTFE/Silicone (PTFE/Sil) combination, known for its resealability and solvent resistance—making it ideal for multiple injections. Some PTFE/Sil septa include a pre-slit design, which helps prevent vial lift-off when the autosampler needle withdraws.

For laboratories seeking a more economical choice, Polyethylene (PE) septa are a popular option, often used with snap seal vials and closures in LC and LCMS workflows. These provide a sufficient seal for general liquid chromatography applications at a lower cost.

Common Septa for GC Vials

In gas chromatography (GC), sample volatility demands a tighter, more secure seal to prevent evaporation and contamination. For this reason, crimp-style closures with aluminum caps are most common. These are typically paired with PTFE/Rubber septa, which combine the inertness of PTFE with the flexibility and compression strength of rubber, ensuring a leak-free seal during injection and heating cycles.

Minimizing Background Noise from Septa

High-sensitivity applications, such as trace analysis or mass spectrometry, can be affected by background interference from septa materials. Chrom Tech offers several specialized septa options to help minimize this:

- Seal 2000 Septa: A specially formulated rubber compound designed to reduce background noise and prevent bleed in GC applications.

- Mass Spec Quality (MSQ) Septa: Used primarily with screw thread closures, these septa pair well with low-adsorption vials to achieve near-zero background interference in LCMS workflows.

For applications such as PFAS analysis, using PTFE-free consumables is essential. Since PTFE-lined septa can contribute to contamination, we recommend using polypropylene snap top vials with PE septa.

Storage Vials and PTFE/F217 Septa

For long-term sample storage, vials with solid-top caps are often lined with PTFE/F217 foam. F217 is a polyolefin foam core sandwiched between two layers of polyethylene—providing excellent resealability after multiple openings. When torqued down to approximately 20 lbs of pressure, the liner compresses to form a tight seal, then rebounds almost fully when released, allowing repeated use without loss of integrity. This makes it ideal for sample storage and standards preparation.

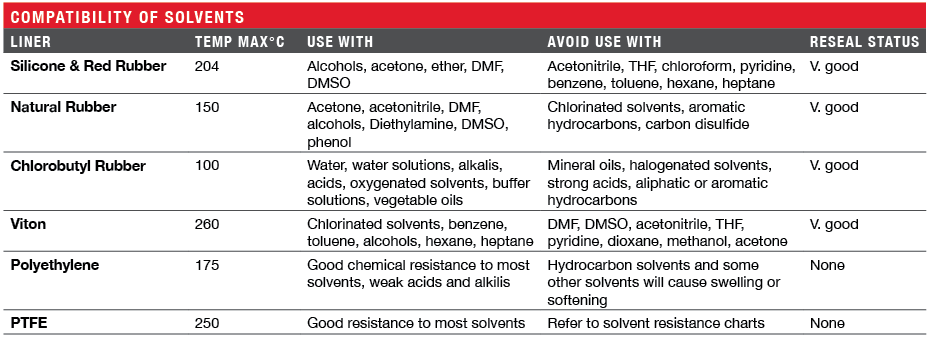

Compatibility of Solvents

Most standard septa materials are compatible with typical chromatography solvents, but it’s still important to verify solvent compatibility before use. The chart below highlights which materials perform best with various solvents and where incompatibilities may occur.

Conclusion

Choosing the correct septa material is crucial for maintaining sample integrity, reducing background noise, and ensuring reproducible results in both LC and GC applications. Chrom Tech offers a wide range of vials, closures, and septa for all analytical workflows. Our experts can help you identify the best combination of vial and septum to fit your analytical and regulatory requirements. Contact our product specialists today for personalized guidance.

Ready to explore all vial types? Visit our Chromatography Vials resource center to compare HPLC, GC, and headspace options in one place.

Frequently Asked Questions About Septa for Chromatography Vials

What is the most common septa material for HPLC vials?

The most common septa for HPLC vials are PTFE/Silicone (PTFE/Sil) combinations. They offer excellent resealability for multiple injections and are compatible with most solvents used in LC analysis.

Why is PTFE/Rubber used for GC vials?

PTFE/Rubber septa create a tight, durable seal ideal for volatile samples and high-temperature GC applications. The rubber core ensures compression strength while PTFE provides chemical resistance.

How can I reduce background noise in mass spectrometry?

Use Mass Spec Quality (MSQ) septa with low-adsorption vials to reduce septum bleed and background interference during LCMS analysis.

What septa should I use for PFAS analysis?

Avoid PTFE-lined septa to prevent PFAS contamination. Instead, use polypropylene snap-top vials with PE septa for a PTFE-free workflow.