Posted by Chrom Tech on 17th Nov 2025

What is the Smallest Sample Volume You Can Use in 96 Well Plates?

For high-throughput laboratories, 96-well plates have become a cornerstone of efficient sample handling. Compared to chromatography vials, they offer significant benefits in cost savings, automation compatibility, and workflow consistency. Well plates enable automated pipetting, reduced consumable use, and simplified data management—making them ideal for analytical, pharmaceutical, and research environments.

Different types of well plates suit different stages of your workflow. For example, you may start with a 1 or 2 mL plate during early processing and later transition to smaller plates for reconstitution or lower sample volumes. However, these transfers can introduce errors, waste time, and risk sample loss. With Chrom Tech’s TrueTaper Well Plates, you can eliminate the transfer step entirely—saving time and improving precision.

Optimized Sample Volumes with TrueTaper Plates

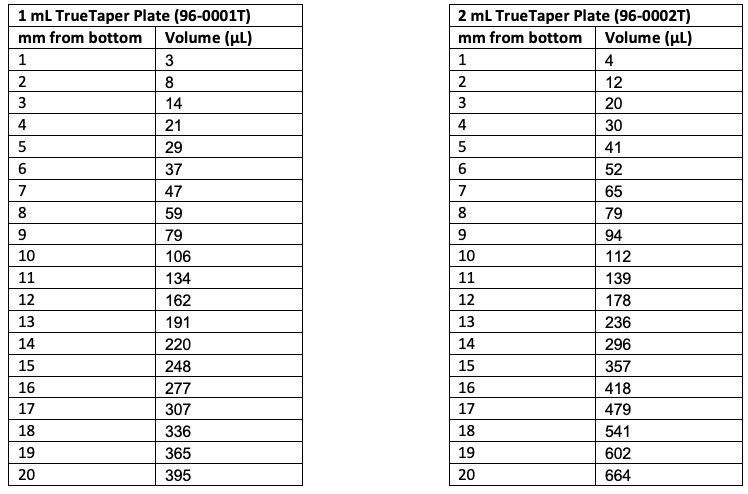

Chrom Tech’s TrueTaper 96-well plates are engineered with precision-tapered wells designed to minimize residual volume and allow for flexible sample handling. Available in both 1 mL and 2 mL well volumes, these plates feature tapered bottoms that hold approximately 50 μL (1 mL plate) and 100 μL (2 mL plate).

Depending on your injector needle depth, you can work with even smaller volumes. The TrueTaper design allows for accurate pipetting and recovery—even at micro-volume levels as low as 3 μL. This versatility eliminates the need for multiple plate transfers, improving both speed and consistency.

By combining low dead volume with high total capacity, TrueTaper plates provide an all-in-one solution for both small and large volume applications. If you’d like to learn more or request a quote, contact our product specialists—we’ll be happy to help you find the best fit for your workflow.

Solutions for Samples Incompatible with Plastic Plates

If your sample is incompatible with plastic plates—for instance, when working with hydrophobic peptides or compounds prone to adsorption—Chrom Tech has you covered. Our Glass Vial Insert 96-Well Plate System offers the inert surface benefits of glass with the automation compatibility of a traditional well plate.

This hybrid system is ideal for sensitive applications that demand precise recovery and low analyte binding, providing researchers with a reliable alternative to standard polypropylene plates.

Well Plate Overview and Expert Support

Whether you’re seeking an in-stock replacement for your current plate or exploring improved solutions for your analytical workflow, Chrom Tech’s well plate selection has options tailored to your lab’s needs. Our team of chromatography specialists is available to assist with product selection, compatibility questions, and technical recommendations.

Visit our website to chat live with a product expert, or email us at sales@chromtech.com for prompt assistance and pricing information.

Looking for More 96-Well Plate Options?

View the complete lineup of polypropylene, deep-well, glass-insert, and specialty plate formats.

Explore All 96-Well PlatesFrequently Asked Questions About 96-Well Plates

What are the main benefits of using 96-well plates over vials?

96-well plates improve efficiency by allowing automated sample handling, reducing consumable costs, and minimizing sample transfer errors. They’re ideal for high-throughput workflows requiring consistent reproducibility.

What makes TrueTaper well plates different?

TrueTaper plates feature a precision-tapered well design that allows accurate handling of both micro and macro volumes, eliminating the need for multiple transfer steps while minimizing sample loss.

Can TrueTaper plates handle very small volumes?

Yes. TrueTaper plates can reliably handle as little as 3 μL while maintaining uniform recovery and reproducibility—ideal for reconstitution or low-volume assays.

What options are available for samples incompatible with plastic?

For hydrophobic or adsorption-prone analytes, Chrom Tech’s Glass Vial Insert Well Plate System provides the inertness of glass with the automation compatibility of standard well plates.