Posted by Chrom Tech on 16th Oct 2025

What are the Advantages of Dual Piston Pumps?

Chrom Tech’s HPLC pumps serve a wide variety of laboratory and industrial applications, many of which extend beyond chromatography. The right pump can dramatically influence the precision, reliability, and efficiency of your system. So, how do you decide which pump best fits your needs? Let’s start by exploring the advantages of dual piston pumps and how they compare to single piston designs.

Improved Flow Accuracy

Flow accuracy is one of the most critical factors in any analytical or process-driven system. Dual piston constant flow pumps are engineered to deliver exceptionally precise flow rates—making them ideal for both HPLC and other continuous flow applications. This accuracy ensures consistency in results, minimizes variability, and enhances the reproducibility of your analyses.

Reduced Pulsation and Noise

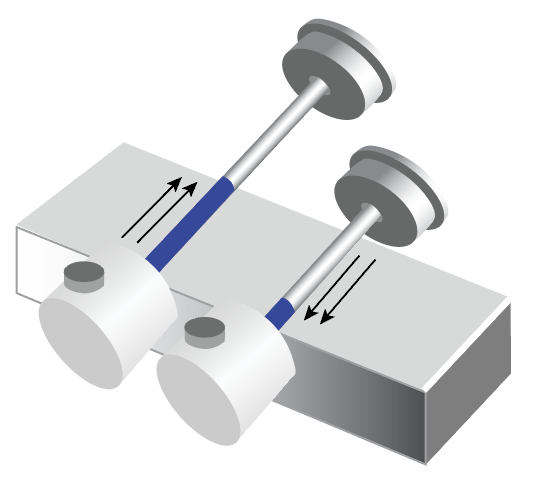

Pulsation can be detrimental to system stability and analytical accuracy. Chrom Tech’s dual piston pumps minimize pulsation through a reciprocating mechanism—while one piston refills, the other continues to push solvent forward, ensuring uninterrupted flow. When combined with a low dead volume pulse dampener, these pumps deliver a virtually pulse-free solvent stream and maintain consistent pressure for superior chromatographic performance.

Dual piston pumps utilize reciprocating pistons—while one delivers solvent, the other refills—greatly reducing pulsation compared to single piston designs.

Key Features of Dual Piston Pumps in Chromatography

Dual piston pumps are specifically engineered for accuracy, stability, and long-term reliability. Below are some of their most notable features:

- Dual-Headed Design: Enables continuous solvent flow for consistent pressure and reliable peak shape in chromatography.

- Positive Displacement Mechanism: Maintains constant fluid delivery essential for both analytical and preparative applications.

- Pulse-Free Operation: Advanced cam motion and pulse dampening deliver near-perfect flow uniformity.

- High Flow Rate Accuracy: Ensures reproducible chromatographic separations and consistent quantitative performance.

- Material Versatility: Available in Stainless Steel, PEEK, and Titanium for compatibility with a wide range of solvents and conditions.

Together, these features make dual piston pumps a preferred choice for users seeking precision and stability in high-performance chromatography or demanding fluid delivery systems.

Higher Flow Rates

Dual piston pumps also excel in achieving higher flow rates while maintaining accuracy. Chrom Tech’s LD/PR dual piston models can reach up to 300 mL/min with outstanding precision across the entire flow range, offering versatility for analytical, preparative, and process-scale applications.

Advantages of Single Piston Pumps

While dual piston pumps provide unmatched flow stability, single piston pumps remain a cost-effective alternative. They deliver dependable performance for applications where slight pulsation is acceptable. Their key advantages include lower purchase cost and simpler maintenance—since only one piston, seal, and check valve assembly requires replacement. For users with less pulsation-sensitive applications, single piston pumps offer excellent value and performance.

Are Dual Piston Pumps Better?

The decision between dual and single piston pumps ultimately depends on your application requirements and budget. Dual piston pumps excel in precision, low pulsation, and long-term reliability, making them ideal for analytical and process systems demanding continuous, pulse-free flow. However, for routine applications, a single piston model may provide sufficient performance at a lower cost.

To learn more about selecting the right pump, explore our guide: 4 Questions You Should Ask Before Buying an HPLC Pump.

Frequently Asked Questions

What makes dual piston pumps more accurate?

Dual piston pumps maintain a continuous flow by alternating pistons—one delivers solvent while the other refills. This eliminates flow interruptions and enhances flow rate accuracy compared to single piston designs.

Do dual piston pumps reduce pulsation?

Yes. The alternating piston design, especially when paired with a pulse dampener, virtually eliminates pulsation. This ensures stable baseline signals and consistent retention times in chromatography.

Are dual piston pumps worth the higher cost?

For applications requiring high precision and flow stability, dual piston pumps offer superior performance and longevity. However, for general-purpose or budget-sensitive applications, single piston pumps can be an economical alternative.