Posted by Chrom Tech on 16th Oct 2025

5 Features to Consider When Choosing a Pump for Continuous Process Applications

Replacing Pharma’s Conventional Batch Processing

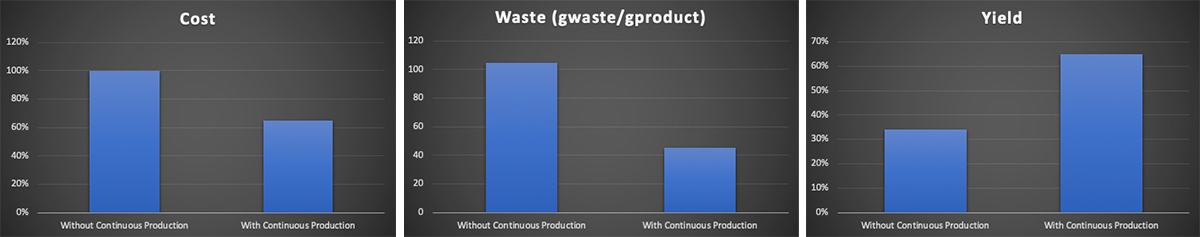

In today’s manufacturing landscape, transitioning from conventional batch chemistry to continuous process applications offers major advantages—reducing waste, improving sustainability, and streamlining time and cost. Continuous flow processing combines chemistry and engineering principles to optimize reaction efficiency and scalability, helping organizations move from lab-scale development to full-scale production more effectively.

While automation and process integration can be complex at first, the benefits are well worth the effort. A crucial early step in establishing a robust continuous process system is identifying the most suitable flow chemistry pump—one that can meet the specific demands of your application, maintain stable operation, and ensure reproducible results.

Source: thechemicalengineer.com

1. Reliability & Maintenance

Reliability is paramount for continuous processes that depend on consistent, uninterrupted operation. Selecting a pump with a strong track record for durability, low downtime, and easy maintenance is essential. Whether you need a compact, economical option for routine analysis or a robust system for industrial use, Chrom Tech pumps deliver dependable performance with exceptional flow accuracy and minimal gradient delay.

Most continuous process users require a dependable “workhorse” pump that can run unattended for extended periods with minimal maintenance. To maximize the lifespan of your pump and prevent leaks or flow inconsistencies, we recommend annual replacement of piston seals and check valves. Replacement parts are listed under “related products” on each pump’s webpage or in the product manual for your specific pump model.

2. Precision & Control

Precision in solvent delivery is key for achieving stable and reproducible results. One major consideration is pulsation—if smooth, consistent flow is critical for your application, a dual piston pump such as our LD or PR class models is ideal. These pumps operate using reciprocating pistons that alternate cycles, minimizing pulsation and ensuring steady flow.

For less pulsation-sensitive applications, the M1 Series single piston pumps offer reliable performance with a compact footprint. If you need additional functionality, consider the LST Class, which includes features like pressure monitoring and a drip tray leak sensor for enhanced safety and convenience.

3. Chemical Compatibility

Choosing the right flow path material ensures long-term compatibility and prevents corrosion or solvent degradation. Chrom Tech pumps are available in PEEK and Stainless Steel, with Titanium and Hastelloy options available for more aggressive chemistries. If you’re unsure about solvent compatibility with your pump’s wetted materials, reach out to our product specialists for expert guidance before making your selection.

4. Flow Rate & Pressure Requirements

Continuous process systems depend on a steady, controlled flow of materials. For this reason, constant flow pumps are the preferred choice for most applications. Chrom Tech’s HPLC pumps—when used as standalone solvent delivery units—provide outstanding precision, consistency, and control across a wide range of flow rates and pressures.

Below is an overview of the flow rate and pressure capabilities across our most popular pump classes:

Keep in mind that solvent viscosity can affect performance. More viscous fluids may require adjustments in flow rate or backpressure to ensure proper operation of check valves and pulse dampeners.

5. Compatibility with Automation Systems

Automation is a key component of most continuous processes. For seamless integration, ensure your pump supports remote control and communication. Chrom Tech pumps are designed with multiple connection options, including RS-232 serial, Micro USB (with hardware driver), and Ethernet ports. Many users connect through existing control software, but a free driver is available for software-based operation when needed.

Conclusion

Choosing the right pump for your continuous process application is about more than specifications—it’s about long-term reliability, precision, and adaptability. By evaluating factors like reliability, control, chemical compatibility, flow range, and automation compatibility, you’ll ensure consistent performance and optimal results. Whether you’re implementing a new continuous flow process or upgrading an existing system, Chrom Tech offers the technology and support to keep your operation running smoothly.

Frequently Asked Questions

What type of pump is best for continuous flow applications?

A constant flow or dual piston pump is ideal for continuous flow applications. These pumps maintain steady solvent delivery with minimal pulsation, ensuring consistent reaction conditions and reproducible results.

How often should pump seals and check valves be replaced?

For most continuous systems, piston seals and check valves should be replaced annually to prevent leaks and maintain accuracy. Regular maintenance extends the lifespan of the pump and prevents unplanned downtime.

Can Chrom Tech pumps integrate with automation systems?

Yes. Chrom Tech pumps support RS-232, Micro USB, and Ethernet connectivity for easy integration into automated systems. Free driver software is also available for remote operation and data control.