13th Dec 2024

PEEK Tubing: What It Is and the Different Types

PEEK Tubing: What It Is and the Different Types

Poly Ether Ether Ketone (PEEK) tubing is widely used in chromatography laboratories and is a popular alternative to stainless steel tubing. It is biocompatible and chemically inert to most commonly used solvents. PEEK tubing is flexible, with a smooth internal surface, and is made from a high-performance engineered polymer known for its mechanical and chemical resistance. It can withstand high temperatures, making it highly resistant to thermal degradation. PEEK has one of the highest strength-to-weight ratios of any thermoplastic, providing the durability needed to endure continuous use under HPLC pressure.

PEEK tubing can handle typical HPLC pressures, up to approximately 10,000 PSI, and has a broad pH range of 0-14. Its smooth internal surface minimizes turbulence compared to similarly sized metal tubing. Among all our polymer tubing materials, PEEK is the least permeable to gas.

How Do You Cut PEEK Tubing?

One of the main advantages of PEEK Tubing is it can easily be cut in the laboratory. Using a PEEK tubing cutter provides the most accurate cut, which enables leak-free HPLC connections. It will provide a clean, burr-free, 90-degree cut for your 1/16” or 1/8” OD tubing. These tubing cutters have guide holes for the tubing to go through, which ensures precise cutting. When purchasing a 5’ length of PEEK tubing, it is important to know that, when they ship from the factory, they are rough cut. A trim cut should be made before use; we recommend the IDEX PEEK tubing cutter.

When Should I NOT Use PEEK Tubing?

The following solvents are usually not recommended for use with PEEK tubing: nitric acid; sulfuric acid; halogenated acids, such as hydrofluoric acid and hydrobromic acid (hydrochloric acid is approved for use in most applications); and pure halogenated gases. Additionally, due to a swelling effect, be cautious in using the following solvents with PEEK tubing: methylene chloride, THF, and DMSO in any concentration and acetonitrile in higher concentrations.

What About Other Types of Polymer Tubing?

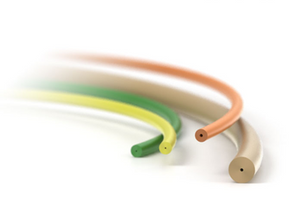

In the chromatography lab, there are multiple types of polymer tubing used; here is a breakdown of the popular types of polymer tubing:

Dupont® FEP Fluoropolymer Tubing

(Fluoronated ethylene-propylene) FEP tubing is a great alternative to traditional PTFE tubing, desirable for use because it is chemically inert to most solvents, easy to cut, and translucent for easy monitoring of solutions passing through. This FEP tubing is great for general, low-pressure applications and is commonly used in the HPLC system between the mobile phase solvent reservoir bottles and the HPLC pump.

ETFE Tubing

(Ethylene-tetrafluoroethylene) ETFE is chemically inert and more suitable for higher pressure applications (when using aqueous mobile phases) than PTFE, FEP, and PFA. Additionally, because ETFE is more rigid than PTFE, FEP, and PFA, this tubing better resists inner diameter collapse. It is also more durable and less gas permeable than PTFE, FEP, and PFA.

Dupont® PFA tubing

(Perfluoroalkoxy alkane) DuPont® PFA tubing offers excellent chemical compatibility; plus, due to its inner surface smoothness, PFA tubing tends to be more translucent than PTFE tubing.