Posted by Chrom Tech on 14th Oct 2025

HPLC Pump Care and Troubleshooting

Routine care and preventative maintenance are key to reliable performance from your Chrom Tech continuous process pumps. Below are common support topics, troubleshooting steps, and maintenance practices to ensure consistent flow, stable pressure, and long component life.

Common Technical Support Topics

- Erratic or inconsistent flow rates

- No flow from the outlet check valve

- Pressure fluctuation or drift

- Visible leakage or fluid seepage

Likely Causes

- Air bubbles or contamination in the check valves

- Worn or scratched pistons and piston seals

- Improperly tightened HPLC fittings

- Unfiltered or poorly degassed solvents

- Plugged inlet filters or incorrect tubing configuration

Preventing Bubbles in HPLC Pumps

Bubbles in the solvent path cause inconsistent pressure and baseline noise. Prevent them by proper solvent preparation and degassing before operation.

Solvent Out-Gassing & Helium Sparging

Dissolved gases (oxygen, nitrogen) can escape during pumping. Sparging with helium for 10–15 minutes before use removes these gases. Maintain a 2–3 psi helium blanket during operation. Mixed solvents (water + acetonitrile or methanol) require active sparging for best performance.

Install a back-pressure regulator after the detector flow cell to prevent out-gassing bubbles and baseline noise.

Cavitation & Reservoir Placement

Cavitation occurs when vapor bubbles form during the inlet stroke. Causes include:

- Crimped or restricted inlet tubing

- Plugged inlet filters

- Tubing longer than 48 in (120 cm) or < 0.085 in (2 mm) ID

- Solvent reservoirs placed below pump level

Always position reservoirs at or slightly above pump level to ensure smooth solvent delivery.

Viscosity & Filtration

High-viscosity solvents may require added inlet pressure. Raise reservoir height or sparge with helium to improve flow. Always filter solvents through a 0.5 µm filter to protect seals and check valves. For buffers or salts, filter frequently and store in sealed, particle-free containers.

Solvents to Avoid

Chrom Tech pump wetted components (stainless steel, ceramic, sapphire, ruby, fluoropolymer) are durable but sensitive to certain chemicals. Avoid using:

- Strong acids such as hydrochloric acid

- Halogenated solvents (chloroform, carbon tetrachloride)

- Ammonium hydroxide and other aggressive bases

For maximum chemical resistance, consider PEEK pump heads where compatible.

Reservoir Placement & Self-Flush Systems

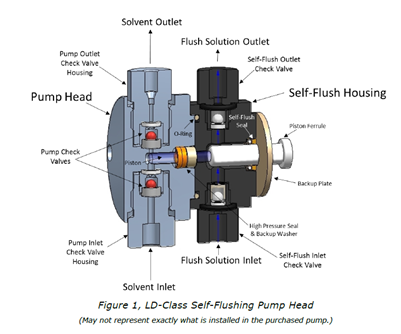

Keep reservoirs near pump height, with short inlet lines to minimize backpressure. For pumps with self-flush heads, continuously wash the piston with flush solvents to prevent salt buildup and abrasion.

- Use 100 % IPA, 100 % methanol, or 20 % IPA/methanol-water

- Avoid using water alone

- Flush regularly when pumping buffers, acids, or volatile solvents like THF or acetone

Routine Maintenance Procedures

1. Inlet Filter Replacement

Inspect filters periodically. Replace if clogged to prevent cavitation. Use 10–20 % organic solvent or a mild biocide when pumping 100 % aqueous solutions to prevent microbial growth.

2. Piston Seal Replacement

Low pressure, leaks, or pressure drift typically indicate worn seals. Replace approximately every 1,000 hours depending on solvent type.

3. Piston Cleaning

Clean gently along the piston length using a folded scouring pad; wipe with an alcohol-dampened lint-free cloth. Avoid perpendicular pressure to prevent scratching.

4. Check Valve Cleaning

- Remove pump head and immerse in ultrasonic cleaner (≈30 min).

- Rinse thoroughly with distilled water.

- Reinstall pump head.

- Run distilled water at 1 mL/min for 15 min to waste.

If issues persist, replace check valves.

5. Flushing Procedure

- Prepare: 100 % IPA, 100 % distilled H₂O, 20 % HNO₃/H₂O (for stainless steel paths).

- Connect outlet to waste; set pump to max flow or PRIME.

- Flush sequentially:

100 % IPA – 3 min → 100 % H₂O – 3 min → 20 % HNO₃ – 3 min (if SS) → H₂O – 3 min → IPA – 3 min.

Conclusion

Most pump performance issues originate from piston seals, check valves, or fittings. Regular maintenance—filter changes, solvent degassing, and seal replacement—ensures consistent operation and extends pump life.

Shop genuine Chrom Tech HPLC accessories and replacement pump parts, including Idex fittings, PEEK tubing, and 316 SS components. Chrom Tech is an authorized Agilent distributor providing certified Agilent parts for HPLC and GC systems.

Frequently Asked Questions

What are the most common issues with continuous process pumps?

Typical issues include erratic flow, no outlet flow, pressure fluctuation, or leaks—usually caused by worn piston seals, contaminated check valves, or insufficient solvent degassing.

How can I prevent bubbles in my HPLC pump?

Degas solvents, sparge with helium, maintain a helium blanket, and use a back-pressure regulator. Keep inlet tubing short and position solvent reservoirs above the pump to avoid cavitation.

Which solvents should I avoid?

Avoid hydrochloric acid, chloroform, carbon tetrachloride, and ammonium hydroxide, which can corrode pump internals. Use inert solvents and compatible flush solutions instead.

How do I extend the life of piston seals?

Use the self-flush feature regularly, filter all solvents, and clean pistons gently. Replace seals per manufacturer recommendations to maintain flow stability.

What maintenance is required?

Inspect inlet filters, check valves, and pistons routinely. Replace components showing wear and flush the system with approved solvents to prevent buildup.

Where can I find replacement parts?

Browse Chrom Tech’s HPLC accessories and pump parts. As an authorized Agilent distributor, Chrom Tech supplies certified components for Agilent, Alltech, and other chromatography systems.

Try Chrom Tech's pump part lookup tool to easily locate replacement parts for you pump.