Posted by Chrom Tech on 14th Oct 2025

Helpful Fluoropolymer Tubing Guide for Your HPLC Applications

What Types of Tubing Are Used in the Laboratory?

In liquid chromatography and general laboratory fluidic systems, a wide range of tubing materials and configurations are available to meet specific needs. When selecting tubing, key factors such as chemical compatibility, pressure tolerance, inner diameter (ID), and optical clarity must be considered. Laboratory tubing options include stainless steel tubing for high-pressure applications and various polymeric materials for low- and medium-pressure use. Among these, fluoropolymer tubing is one of the most popular categories for low-pressure fluidic applications.

What Is Fluoropolymer Tubing?

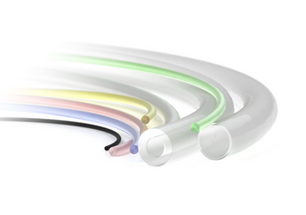

Fluoropolymers are fluorocarbon-based polymers composed of carbon-fluorine bonds that make them highly resistant to chemicals and temperature extremes. The most common example, PTFE (polytetrafluoroethylene), is used throughout the lab in tubing, fittings, and various consumables. Fluoropolymer tubing is generally translucent or transparent, allowing users to visually confirm solvent flow. Its high chemical inertness and smooth inner surface make it ideal for low to medium pressure fluidic pathways.

Types of Fluoropolymer Tubing

Chrom Tech offers several types of fluoropolymer tubing—each optimized for specific laboratory requirements, including pressure limits, clarity, and chemical compatibility.

- PFA Tubing: A smooth inner surface enhances chemical compatibility and flow consistency. PFA tubing is more translucent than PTFE, allowing for easy visual monitoring. Recommended for low-pressure applications (500–2,000 PSI).

- Premium Grade PFA Tubing: Extremely low in contaminants, this high-purity variant is an excellent replacement for PTFE when gas permeability or surface texture are concerns.

- FEP Tubing: Chemically inert and easy to cut, FEP tubing is translucent and available in multiple colors for identification. It has higher pressure limits (2,500–4,000 PSI) and tight manufacturing tolerances for consistency.

- ETFE Tubing: A rigid material that resists inner diameter collapse, ETFE provides excellent solvent resistance and is suitable for medium- to high-pressure applications (500–4,000 PSI) using aqueous mobile phases.

When Is Fluoropolymer Tubing Not Ideal?

Fluoropolymer tubing is not suitable for high-pressure chromatography applications such as HPLC or UHPLC pump-to-column connections. For these areas, stainless steel tubing is the most common and reliable choice, providing superior pressure tolerance and durability. Pre-cut stainless tubing also enables zero dead volume connections for optimal chromatographic performance.

For those needing a biocompatible, flexible alternative, PEEK tubing offers excellent chemical resistance to most common HPLC solvents. It’s easy to cut, available in color-coded sizes, and ideal for moderate-pressure applications.

Additional high-pressure tubing materials include:

- Fused Silica Tubing: Used for micro- and nano-HPLC or capillary electrophoresis due to its precise ID tolerances and ultra-smooth surface.

- PEEKsil Tubing: Combines fused silica with a PEEK outer sheath, providing mechanical strength and compatibility with both metal and polymer fittings. PEEKsil can withstand pressures up to 10,000 PSI.

Determining Which Tubing Goes Where in an HPLC System

Just like HPLC fittings, different sections of your chromatography system require specific tubing types based on pressure zones:

- High-pressure zones: Include the pathway from the pump outlet through the injection valve and the HPLC column. These areas typically exceed 6,000 PSI and require high-pressure tubing made of stainless steel, PEEK, or PEEKsil.

- Low-pressure zones: Include lines from solvent reservoirs to the pump inlet and from the column outlet to waste. Here, fluoropolymer tubing (such as PFA or FEP) and low-pressure fittings are used.

Common low-pressure connections include flangeless fittings (nut and ferrule combinations designed for flat-bottom ports) and luer lock adapters, which are convenient for connecting syringes and removable accessories.

Why Are There So Many Tubing Options?

With so many available materials, choosing the right tubing can feel overwhelming. However, the best tubing is determined by your system’s pressure range, chemical compatibility, and desired flow characteristics. In many cases, several materials may perform adequately, but one will be optimal for your specific conditions. Solvent compatibility charts can simplify the selection process.

If you’re unsure which tubing is best for your setup, our chromatography experts can help. Contact Chrom Tech’s support team for personalized recommendations based on your HPLC or general lab application.

Frequently Asked Questions About Laboratory Tubing

What is the difference between PFA and FEP tubing?

PFA tubing has a smoother internal surface and higher purity, while FEP tubing is slightly more rigid and supports higher pressures. Both are chemically inert and suitable for low- to medium-pressure applications.

Can fluoropolymer tubing be used for HPLC?

Fluoropolymer tubing can be used for low-pressure areas of an HPLC system, such as solvent lines to the pump or waste lines after the detector. For high-pressure sections, stainless steel, PEEK, or PEEKsil tubing should be used instead.

How do I know if my tubing is chemically compatible with my solvents?

Always consult solvent compatibility charts provided by the manufacturer. PFA, FEP, and PTFE are compatible with most solvents, while PEEK may have limitations with strong acids or halogenated solvents.