Posted by Chrom Tech on 7th Nov 2025

Capillary Tubing Selection Guide for Agilent HPLC Systems

Replacing the capillary tubing connections in your HPLC system can feel like an overwhelming task, but Chrom Tech is here to simplify the process. Selecting the right tubing lengths, diameters, and connection types ensures consistent chromatographic performance and minimizes system dispersion. This guide provides practical tips for choosing the ideal capillary tubing for Agilent HPLC systems, helping you achieve optimal system performance with minimal effort.

Selecting the Correct Tubing Length

Each tubing segment in your HPLC system plays a critical role in controlling flow path efficiency. When replacing capillaries, it’s important to match the length to the manufacturer’s specifications for your instrument model. Using tubing that is too long can increase dispersion and backpressure, while tubing that is too short can create tension and poor sealing at connection points.

Chrom Tech provides Agilent replacement capillaries designed for precise fit and reliable performance. Each capillary is engineered to maintain low dead volume, ensuring accurate flow and reproducible chromatography results.

Choosing the Right Inner Diameter (ID)

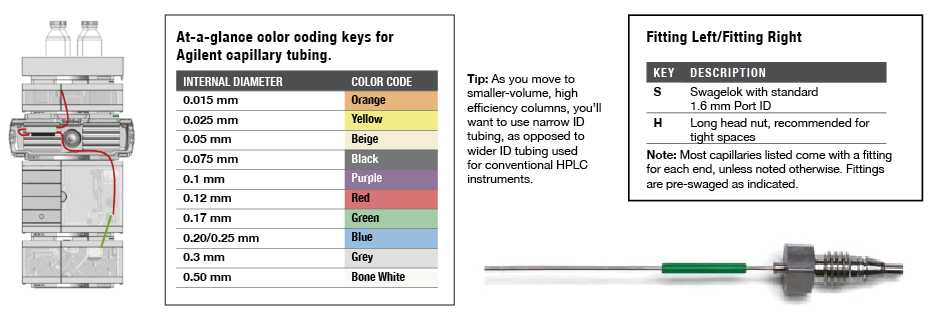

The inner diameter of your capillary tubing determines the balance between flow rate, pressure, and dispersion. Smaller IDs are ideal for UHPLC and high-efficiency separations, while larger IDs are more suitable for traditional HPLC applications or when higher flow rates are required. Selecting the proper ID helps maintain optimal system pressure and peak shape integrity.

- Smaller IDs (≤ 0.12 mm): Minimize dispersion for UHPLC and microflow applications.

- Standard IDs (0.17–0.25 mm): Commonly used in analytical HPLC systems for balanced pressure and flow control.

- Larger IDs (≥ 0.30 mm): Recommended for high-flow or preparative chromatography where pressure is less critical.

Simplifying Column Connections

For users seeking a faster, more reliable column connection, Chrom Tech recommends the InfinityLab Quick Connect and Quick Turn fittings. These fittings ensure a zero-dead-volume seal without the need for wrenches or torque tools, making column changes faster and more consistent. They also help prevent overtightening and damage to column ports, ensuring better long-term system reliability.

Tips for Replacing Agilent Capillary Tubing

- Verify Compatibility: Confirm part numbers and tubing specifications match your specific Agilent model.

- Use Clean Tools: Avoid contamination during installation by using lint-free gloves and clean cutting tools.

- Check for Leaks: After installation, perform a pressure test to ensure tight, leak-free connections.

- Keep Spares On Hand: Stock commonly used capillary lengths and fittings to minimize downtime.

Your Trusted Source for HPLC Supplies

At Chrom Tech, we’re dedicated to simplifying your chromatography setup and maintenance. From replacement Agilent capillaries to InfinityLab fittings, we supply the high-quality components your lab depends on for consistent, accurate separations.

Your one-stop resource for all Agilent LC replacement parts—click through to the main page today.

Chrom Tech is a Minnesota-based, worldwide distributor of chromatography instrumentation and mass spectrometry supplies. We carry vials, well plates, syringe filters, solvent waste containers, and other critical chromatography and spectrometry products. Contact Chrom Tech today to become your trusted supplier for all your analytical lab needs.

Frequently Asked Questions

How do I choose the right capillary tubing for my Agilent HPLC system?

Select capillary tubing that matches your system’s specifications for length and inner diameter. Refer to Agilent’s documentation or Chrom Tech’s capillary selection guide for model-specific recommendations.

What’s the benefit of using InfinityLab Quick Connect fittings?

InfinityLab Quick Connect and Quick Turn fittings eliminate the need for wrenches, create zero-dead-volume seals, and prevent overtightening—streamlining column changes and improving connection reliability.

Can I mix different capillary IDs in my HPLC system?

While possible, mixing different IDs can cause flow inconsistencies and peak distortion. It’s best to use consistent tubing sizes throughout the flow path unless intentionally adjusting dispersion for specific applications.