Glass Inserts in Plates

Glass Inserts in 96-Well Plate Format

Working with hydrophobic peptides, low-level analytes, or adsorption-prone compounds often leads to frustrating sample loss when using standard polypropylene plates. Chrom Tech’s 96-well glass insert plate systems solve this problem by providing an inert, non-reactive surface that protects sample integrity throughout preparation, storage, and LC/MS injection.

Each insert is precision-formed from high-purity glass for exceptional chemical resistance and minimal extractables, ensuring that even the most challenging biomolecules remain in solution. The rigid glass surface eliminates peptide binding, improves analyte recovery, and delivers the consistency required for quantitative mass spectrometry workflows.

Designed for compatibility with all standard 96-well plate automation platforms, these systems maintain SBS/ANSI dimensions while offering superior performance over plastic-based plates. Whether you're handling small-volume proteomics samples, low-adsorption pharmaceutical compounds, or delicate biological extracts, Chrom Tech’s glass insert plates enable cleaner results, higher retention, and more reproducible data.

Looking for More 96-Well Plate Options?

View the complete lineup of polypropylene, deep-well, glass-insert, and specialty plate formats.

Explore All 96-Well PlatesBuild Your Custom 96-Well Micro Plate System

Chrom Tech’s modular 96-well micro plate system allows you to create a high-performance setup tailored to your application needs. Whether you require a flexible multi-tier configuration for stacking inserts or a rigid, thermally conductive aluminum platform for ultra-stable LC/MS workflows, this guide walks you through the components needed to assemble the ideal system.

Step 1: Choose Your Plate System

Start by selecting either the Topas or Acrylic Butyl Styrene Multi-Tier System for modular stacking

flexibility, or the Aluminum Base Plate System for maximum rigidity and superior thermal performance.

Multi-Tier System

| Topas | Acrylic Butyl Styrene | Description | Qty |

|

|---|---|---|---|---|

| 96M-12T | 96M-12 | Base Plate | 1 Piece | |

| 96M-11T | 96M-11 | Collar | 1 Piece | |

| 96M-10T | 96M-10 | Cover | 5 Pieces | |

|

1.0 mL insert requires 1 collar + base plate 1.5 mL insert requires 2 collars + base plate 2.0 mL insert requires 3 collars + base plate |

||||

Aluminum System

For workflows that demand exceptional rigidity and consistent thermal behavior, Chrom Tech’s aluminum base plate system delivers unmatched stability. Its precision-machined design ensures optimal alignment for automated platforms and improves reproducibility in temperature-sensitive LC/MS applications.

| Part No | Description | Qty |

|

|---|---|---|---|

| 96AL-12 | Solid Aluminum Base Plate | 1 Plate | |

| 96AL-14 | Vented Aluminum Base Plate | 1 Plate | |

| 96AL-10 | Aluminum Cover for Base Plate | 1 Piece | |

| 96-05SC | Stainless Steel Screws for 0.5 mL Inserts | 4 Pieces | |

| 96-10SC | Stainless Steel Screws for 1.0 mL Inserts | 4 Pieces | |

| 96-15SC | Stainless Steel Screws for 1.5 mL Inserts | 4 Pieces | |

| 96-20SC | Stainless Steel Screws for 2.0 mL Inserts | 4 Pieces |

Step 2: Select Your Glass Inserts

All inserts arrive pre-loaded in a 96-position plate loader for quick, tool-free alignment with your chosen system.

| Flat Bottom | Conical | Round Bottom | Volume |

|

|---|---|---|---|---|

| 96I-0450F | 96I-0450 | — | 0.5 mL | |

| 96I-04100F | 96I-04100 | 96I-04100R | 1.0 mL | |

| 96I-04150F | 96I-04150 | 96-04150R | 1.5 mL | |

| 96I-04200F | 96I-04200 | 96I-04200R | 2.0 mL |

Step 3: Add a Sealing Liner

Finish your system by securing your inserts with an inert PTFE/silicone liner.

This creates a contamination-free environment and prevents sample evaporation during handling and storage.

| Part No | Description |

|

|---|---|---|

| 96M-16 | Molded PTFE/Silicone Liner, 96 Plugs (5/pk) | |

| BST-9790 | 2 mil PTFE Sealing Tape*, 100/pk | |

| *The BST-9790 provides an economical dust cover for non-critical sealing needs. | ||

Key Definitions

▸Base Plate

The foundational support platform used in both multi-tier and aluminum 96-well plate systems. Provides structural alignment for inserts and collars.

Collar (Spacer)

Plastic or Topas ring that positions the glass insert at the correct height. Additional collars increase the insert’s elevation to match required working volumes.

Glass Insert

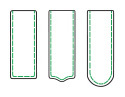

Precision-formed borosilicate glass wells designed to prevent analyte adsorption, ideal for LC/MS workflows. Available in flat, conical, or round-bottom geometries.

Flat Bottom Insert

Insert style featuring a flat internal surface, optimized for evaporation studies, solvent evaporation, and general sample prep workflows.

Conical Insert

A tapered-bottom insert that concentrates samples into a narrow point, improving recovery for low-volume or low-concentration analytes.

Round Bottom Insert

Curved-bottom insert that improves mixing and vortexing efficiency, commonly used in biological workflows.

PTFE/Silicone Liner

A chemically inert sealing layer used to secure inserts, prevent contamination, and reduce evaporative loss during storage.

Plate Loader

A precision-aligned loading frame that holds 96 glass inserts in a fixed arrangement, enabling quick transfer into multi-tier or aluminum base systems.

Frequently Asked Questions

▸Are Chrom Tech’s glass insert systems compatible with standard 96-well plate automation?

Yes. All components adhere to SBS/ANSI 96-well plate dimensions, making them compatible with liquid handlers, autosamplers, and robotic systems used in LC/MS workflows.

Why would I choose a glass insert instead of a polypropylene well?

Glass provides an inert, non-adsorptive surface that prevents hydrophobic peptides, metabolites, and small molecules from sticking—improving sample recovery and quantitation accuracy.

How do I know how many collars are needed for each insert?

Insert height determines collar requirements:

• 1.0 mL insert → 1 collar + base plate

• 1.5 mL insert → 2 collars + base plate

• 2.0 mL insert → 3 collars + base plate

These stacks position the top of the glass insert flush with the plate system for consistent pipetting.

Does Chrom Tech offer sealing solutions for the assembled plates?

Yes — you can pair your system with molded PTFE/silicone liners or PTFE sealing tape, depending on whether you need a full inert seal or a simple dust-cover option.

Can this system be used for heated or temperature-controlled workflows?

The aluminum base plate system provides excellent thermal conduction and is recommended for temperature-dependent LC/MS and sample prep workflows. Multi-tier polymer systems can be used for ambient applications.