Posted by Chrom Tech on 15th Oct 2025

When To Use PEEK Tubing Over Stainless Steel Tubing in HPLC

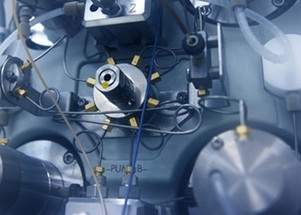

PEEK tubing and stainless steel tubing are both widely used in HPLC systems, but the decision between them depends on application requirements, pressure ratings, solvent compatibility, and budget. PEEK (Polyether Ether Ketone) is a high-performance engineered polymer prized for its excellent mechanical strength, chemical resistance, and thermal stability. Its smooth internal surface and inertness to most solvents make it ideal for achieving sharp chromatographic peaks and reproducible results.

When to Choose PEEK Tubing

PEEK tubing offers several practical and performance advantages for laboratories seeking flexible, cost-effective, and chemically inert solutions.

1. PEEK Tubing Is More Affordable and Easier to Work With

One of the most attractive advantages of PEEK tubing is its affordability and ease of customization. It can be purchased in rolls and easily cut to any desired length using a proper PEEK tubing cutter. Chrom Tech’s polymer tubing cutter ensures a precise, burr-free, 90° cut for 1/16” or 1/8” outer diameter tubing—resulting in leak-free connections.

In contrast, stainless steel (SS) tubing requires specialized cutting tools and precision techniques to achieve a burr-free finish. For most applications, we recommend using pre-cut stainless steel tubing to save time and prevent flow path imperfections.

Because PEEK is sold in continuous coils, it’s easy and economical to re-plumb your HPLC system with the exact lengths you need. Cutting stainless steel tubing in-lab is far more challenging and can lead to deformation or contamination of the tubing ends. To help decide whether to cut your own SS tubing, see our blog To Cut or Not to Cut.

2. PEEK Tubing Is Bioinert

For biocompatible and protein-based analyses, PEEK tubing is the preferred option. It is completely metal-free and does not introduce metal ions that could denature proteins or interfere with bioseparation results. In any system requiring a fully bioinert flow path, such as peptide, protein, or biomolecule analysis, PEEK tubing is the obvious choice.

When to Choose Stainless Steel Tubing

While PEEK tubing excels in convenience and biocompatibility, stainless steel remains the standard for high-pressure, solvent-diverse applications.

1. Stainless Steel Tubing Handles Higher Pressure

Stainless steel tubing is essential for Ultra-High-Pressure Liquid Chromatography (UHPLC) and other demanding applications. While PEEK tubing typically handles up to ~5,000 psi (depending on fittings and system configuration), properly installed stainless steel tubing can operate safely at pressures up to 20,000 psi or more. This makes stainless steel the tubing of choice for high-pressure analytical and preparative HPLC systems where flow integrity is critical.

2. Stainless Steel Offers Superior Solvent Compatibility

Although PEEK is chemically resistant to most common solvents, it can swell or degrade when exposed to certain aggressive chemicals, including:

- Dichloromethane (DCM)

- Tetrahydrofuran (THF)

- Dimethyl sulfoxide (DMSO)

- Concentrated nitric or sulfuric acid

For applications involving these solvents—or in cases where temperature and pressure extremes are common—stainless steel tubing is the more reliable option.

Summary: Choosing Between PEEK and Stainless Steel

The choice between PEEK and stainless steel tubing ultimately depends on your analytical needs:

| Feature | PEEK Tubing | Stainless Steel Tubing |

|---|---|---|

| Pressure Rating | Up to ~5,000 psi | Up to ~20,000 psi |

| Chemical Compatibility | Inert to most solvents | Compatible with all solvents |

| Ease of Cutting | Easy to cut in-lab | Requires precision cutting tools |

| Bioinert Properties | Yes — ideal for bioseparations | No — potential for metal ion leaching |

| Cost | Lower | Higher |

Conclusion

PEEK tubing is an excellent choice for biocompatible, moderate-pressure HPLC applications and is ideal for laboratories seeking flexibility and cost efficiency. However, for high-pressure or chemically aggressive environments, stainless steel tubing remains the superior option. Each has its place in chromatography, and selecting the right one ensures reliable performance and system longevity.

For guidance on selecting the best tubing for your system, contact Chrom Tech’s technical support team at sales@chromtech.com or browse our full selection of HPLC accessories today.

Frequently Asked Questions About PEEK and Stainless Steel Tubing

When should I use PEEK tubing instead of stainless steel?

Use PEEK tubing when you need a chemically inert, bioinert, and easy-to-cut option for moderate-pressure HPLC applications. It’s ideal for biocompatible systems and general analytical work below 5,000 psi.

Can PEEK tubing be used in UHPLC systems?

Generally, no. PEEK tubing cannot withstand the extremely high pressures of UHPLC systems, which often exceed 15,000 psi. Stainless steel tubing is recommended for these applications.

Is PEEK compatible with all HPLC solvents?

No. While PEEK is resistant to most solvents, it is not compatible with dichloromethane (DCM), tetrahydrofuran (THF), DMSO, or strong acids like nitric and sulfuric acid, which can cause swelling or degradation.