Posted by Chrom Tech on 17th Nov 2025

Using 96 Well Plates In High Throughput Laboratories

For high-throughput laboratories, switching from traditional autosampler vials to 96-well plates offers substantial advantages—particularly in automation, consistency, and time savings. While not every step in an analytical workflow can be automated, certain instruments can significantly enhance reproducibility and throughput for LC/MS assays. Below, we outline three essential tools that streamline sample preparation, evaporation, and sealing for 96-well plate workflows.

-

1. Positive Pressure Manifolds for Solid Phase Extraction (SPE)

Reliable sample preparation instrumentation is crucial for successful solid phase extraction. Traditionally, vacuum manifolds are used to pull solvents through the SPE media; however, they often introduce inconsistencies. When individual wells run dry, vacuum is redirected through the empty ports, slowing flow through the remaining wells and creating variability in analyte recovery.

To eliminate this issue, Chrom Tech recommends the Positive Pressure Manifold. This system applies even, regulated pressure across all wells—whether dry, wet, or filled—ensuring consistent flow through every sample. Its restricted-flow gas ports prevent uneven vacuum distribution, providing superior flow control even with viscous or challenging matrices. Operating pressures up to 75 PSI allow smooth, adjustable flow for a wide range of applications, making this manifold the ideal choice for reproducible SPE performance in high-throughput environments.

-

2. Speeding Up the Dry Down Step

Evaporation, or “dry down,” is one of the most time-consuming steps in sample prep. The Ultravap Mistral 96-Well Plate Evaporator is Chrom Tech’s top recommendation for reducing dry down times in high-throughput LC/MS workflows. This programmable evaporator allows precise control of nitrogen temperature, flow rate, and needle depth—keeping the gas just above the liquid surface to accelerate evaporation.

In real-world applications, labs have reported cutting dry down times by up to 50% with aqueous protein samples compared to other evaporators. With the ability to store 15 password-protected methods, the Ultravap Mistral ensures consistency and compliance across multiple users while maximizing throughput for repetitive workflows.

-

3. Properly Sealing the 96-Well Plate

Proper plate sealing is critical for LC/MS assays to prevent sample evaporation, cross-contamination, and environmental exposure. While options like silicone mats and adhesive films exist, they often lack the precision or automation needed for high-volume workflows. For frequent sealing operations, Chrom Tech recommends the UltraSeal Pro Thermal Plate Sealer.

This thermal plate sealer automates the sealing process with password-protected controls for temperature, pressure, and sealing time—ensuring repeatable results and regulatory compliance. A single roll of foil can seal up to 4,800 plates, providing excellent cost efficiency. Users can simply load the plate, press “Seal,” and achieve a consistent, pierceable seal ideal for high-throughput LC/MS environments.

Chrom Tech’s 96-Well Plate Instrumentation Trifecta

To fully realize the benefits of 96-well plate workflows, pairing your plates with optimized instrumentation is essential. Chrom Tech’s recommended trifecta—Positive Pressure Manifold, Ultravap Mistral Evaporator, and UltraSeal Pro Thermal Plate Sealer—offers complete automation compatibility, reproducibility, and time savings. These tools together enable laboratories to streamline SPE, evaporation, and sealing steps for a seamless, efficient workflow.

To learn more about integrating 96-well plate automation into your lab, contact our product specialists or visit chromtech.com to request a personalized consultation.

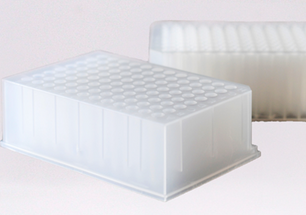

Looking for More 96-Well Plate Options?

View the complete lineup of polypropylene, deep-well, glass-insert, and specialty plate formats.

Explore All 96-Well PlatesFrequently Asked Questions About 96-Well Plate Instrumentation

Why is a positive pressure manifold better than a vacuum manifold?

Positive pressure manifolds apply even gas pressure across all wells, ensuring consistent solvent flow and analyte recovery. Unlike vacuum systems, they prevent uneven drying and eliminate variations caused by pressure loss in empty wells.

How does the Ultravap Mistral improve evaporation efficiency?

The Ultravap Mistral allows precise control over nitrogen flow and temperature, reducing evaporation times by up to 50% while maintaining sample integrity—making it ideal for protein or aqueous samples.

What advantages does the UltraSeal Pro Thermal Plate Sealer offer?

This automated thermal plate sealer ensures consistent, airtight seals with programmable temperature and pressure settings. Its password protection supports compliance and minimizes operator variability in high-throughput labs.

Can these instruments be used together in an automated workflow?

Yes. Chrom Tech’s Positive Pressure Manifold, Ultravap Mistral Evaporator, and UltraSeal Pro Sealer are all designed for compatibility with automated LC/MS sample prep workflows, enhancing throughput and reproducibility.