Ultra Inert Press Fits

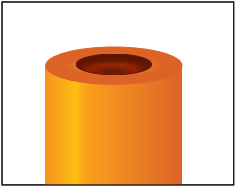

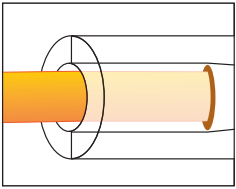

In the past it was necessary to use press-fit connectors with specific dimensions to connect columns of those dimensions. Modern press-fit connectors are 'laser-milled' to provide highly reproducible taper angles throughout the length of the press-fit, ensuring an excellent seal. The press-fits are now treated with Agilent Ultra Inert deactivation to provide a robust and inert flow path.

Glass unions can be sealed with polyimide sealing resin which ensures a leak-free and solid connection. This method is recommended if glass press-fit unions are used.

| Description | Part No. |

|---|---|

| Resin, Capillary Sealing, 5 grams — Dangerous Good | 500-1200 |

| Y-splitter, Ultra Inert, universal press fit | 5190-6980 |

| Universal Press Fit Union, Ultra Inert, for 0.10 – 0.75 mm, 10/pk | 5190-6979 |

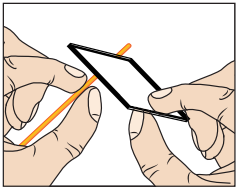

Step 1: Lightly scribe the column with a wafer cutter (p/n 5181-8836).

Step 2:Gently break the column apart.

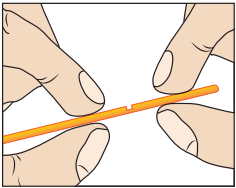

Step 3: Inspect the column end for a clean, smooth cut using a magnifier (p/n 430-1020). Wipe the end of the column with isopropyl alcohol and a lint-free cloth.

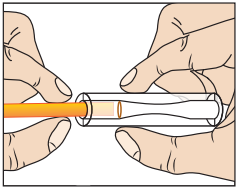

Step 4:Grasp the column near the end and insert it into the Press Fit connector. Push the two straight together firmly.

Step 5:Inspect the connection using the magnifier. A brown ring around the end of the column indicates a leak-free seal. A slight tug ensures accuracy. Optionally, apply polyimide sealing resin to secure capillary columns. Always check for leaks before and after thermal cycling.