Posted by Chrom Tech on 15th Oct 2025

Tips for How to Prime an HPLC Pump

Properly priming your HPLC pump is one of the simplest yet most essential steps in maintaining reliable system performance. Whether you’re setting up a new system, switching solvents, or restarting after storage, ensuring your pump is fully primed prevents air bubbles, protects pump seals, and ensures accurate solvent delivery throughout your chromatography workflow.

Why It’s Important to Prime an HPLC Pump

Priming ensures that the pump head and solvent lines are completely filled with mobile phase—without trapped air bubbles that can lead to pressure fluctuations or inaccurate flow rates. Air in the lines can cause retention time variability, inconsistent baselines, and even damage to pump seals over time. Proper priming also guarantees that only the desired solvent is flowing through your system, eliminating contamination from previous solvents.

Step-by-Step: How to Prime an HPLC Pump

If your HPLC pump is equipped with a prime/purge valve, priming is quick and straightforward. Before beginning, make sure all connections downstream of the valve are closed.

- Confirm all connections downstream of the prime/purge valve are closed.

- Attach a syringe to the prime/purge valve port.

- Open the prime/purge valve (for Chrom Tech pumps, turn the knob counterclockwise one to two turns).

- Draw the syringe back to pull approximately 20 mL of solvent through the system.

- Press the “Prime” button (or set the pump to maximum flow) and continue drawing until no bubbles appear in the solvent line.

- Close the prime/purge valve.

- Stop the prime function and remove the syringe.

What Does the Prime/Purge Valve Do?

The prime/purge valve vents solvent flow to atmosphere, allowing efficient removal of air from the system. When closed (clockwise), pressure is directed through the outlet port for normal operation. When opened (counterclockwise), pressure is vented, and solvent exits the drain port—making it easy to pull solvent through with a luer syringe and purge trapped air bubbles.

No Prime/Purge Valve? No Problem.

If your pump doesn’t have a built-in prime/purge valve, you can still prime manually using standard HPLC fittings. Simply remove the 10-32 fitting on the outlet check valve (the standard outlet port size for most HPLC pumps), insert a P-642 female luer adapter, attach a luer syringe, and draw solvent through the pump head until no air remains.

P-642 female luer adapter shown above

Chrom Tech HPLC Pumps: Built for Easy Maintenance

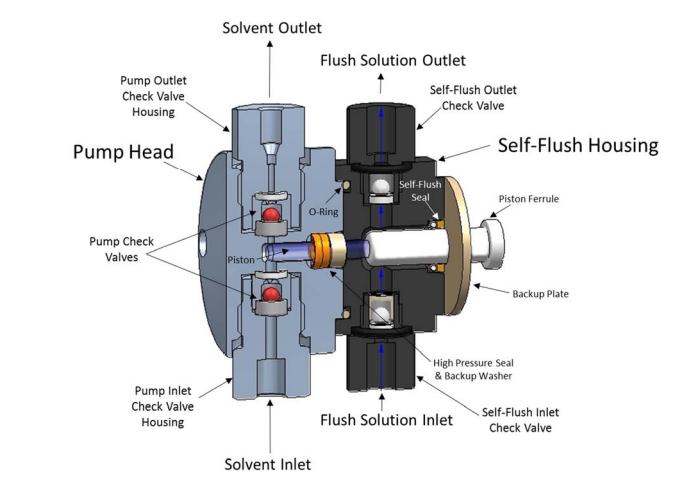

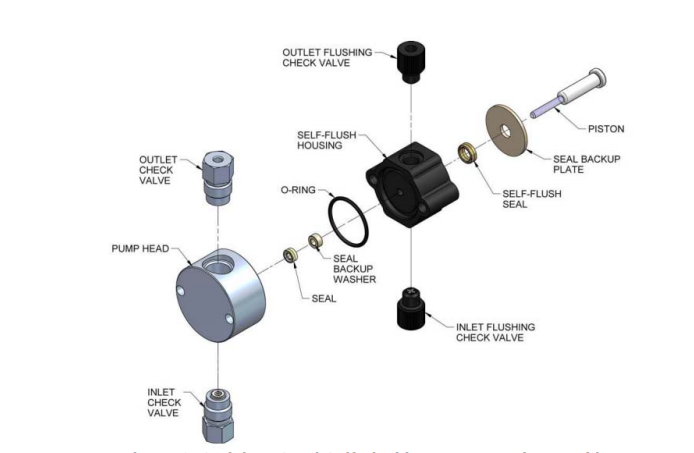

Chrom Tech HPLC pumps are engineered for straightforward maintenance. The inlet check valve is located on the bottom of the pump head, and the outlet check valve is on the top—both easily accessible without disassembling the chassis. The exploded diagram below illustrates the self-flush housing and valve locations.

Every Chrom Tech pump features a Self-Flush system that continuously wets the piston to prevent salt buildup and buffer crystallization. This proactive design dramatically extends seal life and maintains long-term performance by preventing scratches on the piston surface and leaks caused by seal wear.

For more pump care advice, read our related guide: HPLC Pump Care and Troubleshooting.

Customer Spotlight: Chrom Tech Pumps in Production

Chrom Tech HPLC pumps are not only trusted in analytical labs—they’ve been running continuously in industrial production environments for over 20 years. One long-time customer, Cody Bullis, Equipment Maintenance Technician Supervisor at Cantel Medical, shared this insight:

“We can trust that the Chrom Tech pumps are consistent every time. That’s why we chose Chrom Tech when we needed to expand our diluent lines. The products are reliable, but it’s the support that stands out—Chrom Tech always responds quickly and helps us find a solution. We have 75 Chrom Tech pumps in operation and continue to choose Chrom Tech because of the quality, service, and relationship we’ve built.”

Chrom Tech HPLC pumps have been trusted in production facilities like Cantel Medical for decades—offering consistent performance, accessible maintenance, and dedicated technical support.

Frequently Asked Questions About Priming HPLC Pumps

How often should I prime my HPLC pump?

You should prime your pump whenever you change solvents, after pump maintenance, or when taking a system out of storage. Regular priming ensures consistent flow and prevents air from entering the system.

What happens if I don’t prime my HPLC pump?

Unprimed pumps may contain trapped air, leading to pressure fluctuations, inaccurate flow rates, and potential seal damage. Over time, this can cause poor chromatographic performance or even system failure.

Can I prime without a prime/purge valve?

Yes. Using a luer adapter like the P-642 and a syringe, you can manually draw solvent through the pump to remove air bubbles and fully prime the system.