Posted by Chrom Tech on 15th Oct 2025

The Difference Between Superficially Porous and Fully Porous Particles

In liquid chromatography, the particle design of an HPLC column directly affects resolution, efficiency, and pressure. The two most common types—superficially porous particles (SPPs) and fully porous particles (FPPs)—offer distinct advantages depending on the analysis. Understanding the differences between these two designs helps chromatographers select the most efficient column for their application.

Why Use a Superficially Porous Particle?

Superficially porous particles (also known as solid-core or core–shell particles) have a solid, nonporous core surrounded by a thin, porous shell. This design reduces the diffusion distance for analytes, resulting in faster separations and higher efficiency. Because of their tighter particle size distribution, SPP columns also provide excellent peak shapes and reproducibility.

Superficially porous columns are compatible with both HPLC and UHPLC systems. Their combination of speed, resolution, and moderate backpressure makes them a preferred choice for laboratories developing or optimizing chromatographic methods.

Superficially Porous vs. Fully Porous Particles

Fully porous particles are uniformly porous throughout, allowing analytes to diffuse into the entire particle. While effective, this increases diffusion time and can reduce separation efficiency compared to superficially porous designs of the same size.

By contrast, SPPs maintain high efficiency at lower or comparable backpressure. This advantage enables shorter run times and higher throughput without exceeding instrument pressure limits. Many superficially porous columns are available in multiple particle sizes and stationary phase chemistries, providing flexibility across analytical needs.

How Particle Size Affects Pressure

Column backpressure increases inversely with the square of particle size. Smaller particles create more resistance to flow, raising system pressure. One of the key advantages of superficially porous particles is that they deliver high efficiency similar to sub-2 µm fully porous particles—but with lower backpressure. This makes them ideal for achieving faster analyses on standard HPLC systems.

For more details on how pore and particle size influence performance, see our guide on pore size vs. particle size in HPLC columns.

Understanding Backpressure in HPLC

Backpressure is the resistance generated by the components in an HPLC system—mainly the column—against the flow of solvent from the pump. Superficially porous particles produce lower backpressure because analytes travel shorter distances through each particle, improving mass transfer efficiency and reducing overall resistance.

Other Causes of High Pressure in HPLC

Aside from column packing, high pressure can also result from in-line filters, guard columns, or tubing with smaller internal diameters. Pressure is affected by solvent viscosity, flow rate, tubing length, and internal diameter (ID). Even slight variations within manufacturer tolerances (e.g., 0.004–0.006" ID) can influence total system pressure.

Chrom Tech provides an Excel-based Pressure Drop Calculator to help you estimate tubing backpressure under different conditions. Email our technical team to request a copy.

Most Widely Used HPLC Techniques

Reversed-phase chromatography remains the most commonly used technique in HPLC. Among Chrom Tech’s offerings, the Agilent Poroshell EC-C18 (end-capped) and SB-C18 (non-endcapped) columns are customer favorites for their reliable performance and reproducibility.

Analyzing Polar Compounds With Superficially Porous Columns

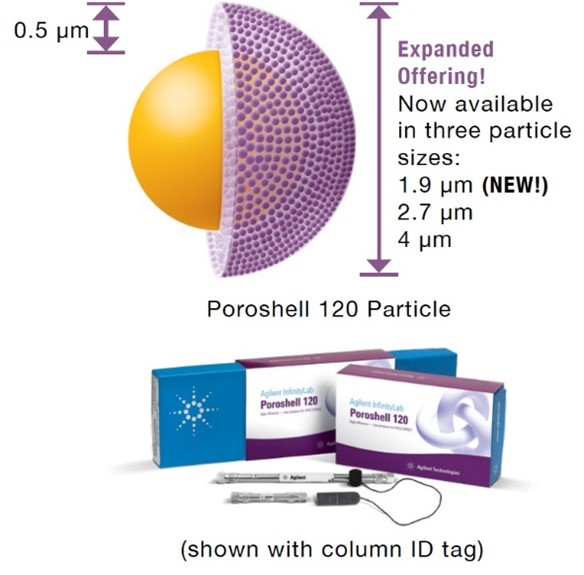

Agilent’s InfinityLab Poroshell 120 HILIC columns extend the advantages of superficially porous technology to polar analytes. They enable strong retention of small, hydrophilic molecules using common reversed-phase solvents.

- Poroshell 120 HILIC-Z: Zwitterionic phase for charged compounds with excellent peak shape—even under high-pH or high-temperature conditions.

- Poroshell 120 HILIC-OH5: Poly-hydroxy fructan phase offering unique selectivity for challenging polar analytes.

These Poroshell columns deliver high efficiency, robustness, and long lifetimes—making them ideal for both routine and advanced LC applications. For more options, explore Chrom Tech’s full selection of HPLC syringe filters and column accessories.

Frequently Asked Questions About Porous Particles in HPLC

What is the main advantage of superficially porous particles?

Superficially porous particles provide higher efficiency and faster separations at lower backpressure than fully porous particles of the same size, improving resolution without requiring UHPLC-level pressure.

Can superficially porous particles be used in both HPLC and UHPLC systems?

Yes. These particles are compatible with both HPLC and UHPLC systems, making them versatile choices for method development and routine analysis.

Do superficially porous particles reduce system pressure?

They often generate less backpressure than fully porous particles because analytes travel shorter diffusion paths through the particle structure.