Sealing Films & Foils

Sealing Films, Foils, and Tapes

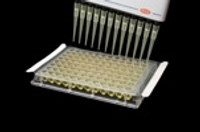

Chrom Tech offers a comprehensive selection of sealing films, foils, and laboratory sealing tapes designed to protect samples in 96-well and 384-well microplates. These sealing solutions provide reliable defense against evaporation, cross-contamination, and environmental exposure—making them an essential component of high-quality sample preparation and storage workflows.

Choose adhesive sealing films for rapid, pierceable closure during routine assays, or opt for heat-seal foils when long-term, tamper-resistant protection is required. With options suitable for both manual benchtop workflows and fully automated platforms, Chrom Tech provides sealing materials that deliver clarity, consistency, and dependable performance.

- Pierceable adhesive films suitable for both manual and automated applications

- Heat-seal foils offering exceptionally strong, long-term sealing stability

- Compatible with ANSI/SLAS-standard 96-well and 384-well plate formats

- Available as precut sheets or high-capacity rolls for high-throughput workflows

- A cost-effective alternative to friction seals and silicone/PTFE cap mats

Whether you require flexible, easy-to-apply films or durable foil-based sealing for long-term storage, Chrom Tech delivers proven solutions engineered for accuracy and efficiency across sample preparation, incubation, transport, and analytical workflows.

For application guidance or questions regarding compatibility with your microplate format, please contact our technical support team.

Resources

Well Plates BrochureLooking for More 96-Well Plate Options?

View the complete lineup of polypropylene, deep-well, glass-insert, and specialty plate formats.

Explore All 96-Well PlatesKey Definitions

▸A pressure-sensitive film that adheres directly to a microplate surface, providing quick, pierceable sealing for routine assays and automated workflows.

A foil-based sealing material applied using a heat sealer, offering long-term, tamper-resistant protection against evaporation and contamination.

The ability of a sealing material to allow autosampler needles or pipette tips to penetrate while maintaining an effective seal.

The prevention of sample loss due to evaporation—critical for assays involving heating, long incubations, or low-volume samples.

A continuous roll of sealing film designed for high-throughput environments, reducing changeover time during automated processing.

The industry footprint standard that ensures sealing films and foils align correctly with 96-well and 384-well plates for automated workflows.

Frequently Asked Questions

▸When should I choose adhesive films over heat-seal foils?

Adhesive films are ideal for quick sealing and workflows requiring pierceable access, while heat-seal foils provide long-term, tamper-resistant protection for storage, transport, or thermal cycling.

Are your sealing films and foils compatible with automated systems?

Yes. Many Chrom Tech sealing films are automation-friendly and available in roll format, making them suitable for plate handlers, robotic systems, and high-throughput screening platforms.

Do sealing films prevent evaporation during incubation?

Yes. Both adhesive and heat-seal options significantly reduce evaporation, making them suitable for heated assays, overnight incubations, and low-volume samples.

Are Chrom Tech sealing materials pierceable for autosampler use?

Most adhesive films are pierceable, allowing needle access for LC/MS and automated pipetting. Heat-seal foils may require specific foil types depending on pierceability requirements.

Can I use these sealing products with both 96-well and 384-well plates?

Yes. All Chrom Tech sealing films, foils, and tapes are compatible with ANSI/SLAS-standard 96-well and 384-well microplates.