Posted by Chrom Tech on 15th Oct 2025

What Is the Difference Between Liquid Liquid Extraction and Supported Liquid Extraction?

Both Liquid-Liquid Extraction (LLE) and Supported Liquid Extraction (SLE) are widely used techniques for separating analytes based on their solubility in immiscible phases. While the principles are similar, the workflow and efficiency differ significantly. Understanding these differences is essential when choosing the best method for your analytical workflow—especially in applications such as drug testing, environmental analysis, and clinical research.

What Is Liquid-Liquid Extraction (LLE)?

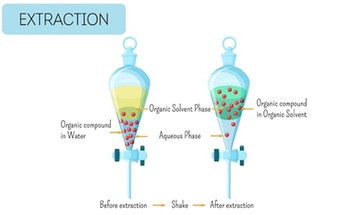

Liquid-Liquid Extraction (LLE) is a classic and reliable separation technique that partitions analytes between two immiscible liquids—an aqueous layer and an organic solvent layer. After thorough mixing, compounds distribute according to their relative solubilities. Typically, organic compounds move into the organic layer while salts remain in the aqueous layer.

LLE often requires vigorous mixing, centrifugation to break emulsions, and careful handling to achieve reproducible phase separation. While LLE is highly effective, it is labor-intensive and can be difficult to automate, making it less ideal for high-throughput laboratories.

How a Separatory Funnel Works in LLE

The separatory funnel is the traditional tool used in LLE. It allows the operator to mix, separate, and isolate phases efficiently:

- Select two immiscible solvents—typically an aqueous and an organic solvent.

- Add both to the funnel and shake gently to increase contact surface area and promote analyte transfer.

- Allow settling—the denser liquid forms the bottom layer.

- Drain the layers—collect the solvent containing the target analyte for analysis.

While simple in concept, this process can take hours or even days depending on sample viscosity, volume, and solubility characteristics. Manual handling also introduces variability and the potential for emulsion formation, which complicates automation.

LLE Setups for Less Dense Solvents

When working with solvents lighter than water (e.g., diethyl ether), several apparatus modifications can improve extraction efficiency:

- Removable fritted glass tube: Allows for continuous extraction and phase separation.

- Solvent return control tap: Ensures efficient solvent recovery while preventing losses.

- Adjustable apparatus: Enables flexibility for varying solvent densities and extraction conditions.

Proper calibration and secure fittings are essential before beginning the extraction to ensure consistent, reproducible separations.

What Is Supported Liquid Extraction (SLE)?

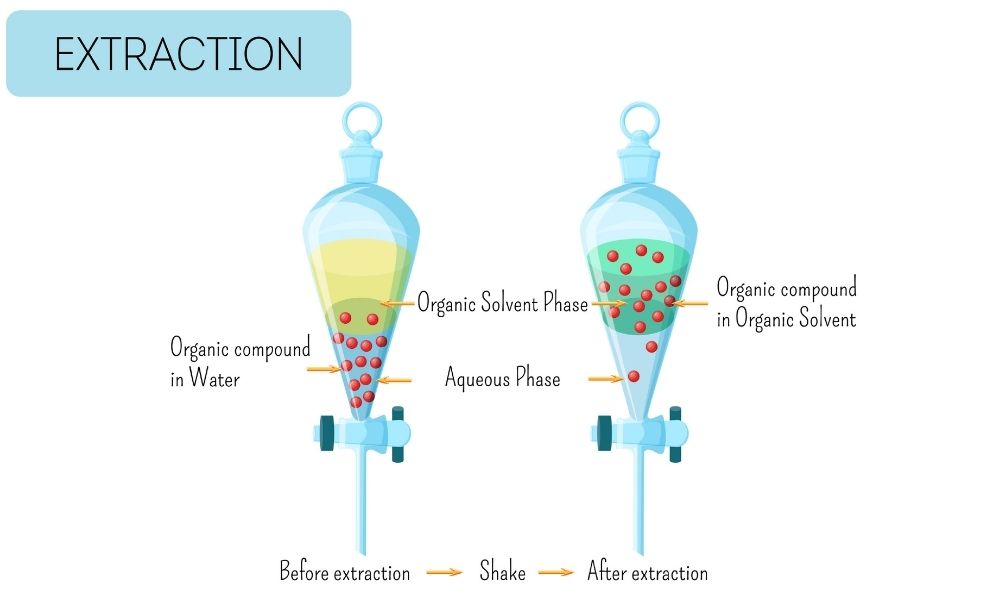

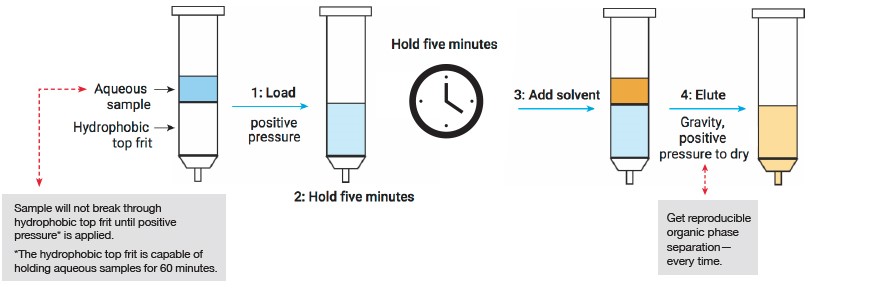

Supported Liquid Extraction (SLE) is an advanced evolution of LLE that simplifies the workflow while improving reproducibility. Instead of manual shaking and phase separation, SLE uses a solid support—typically diatomaceous earth—to immobilize the aqueous sample as a thin film. A water-immiscible solvent then passes through the support bed, efficiently extracting analytes into the organic phase.

This design eliminates the mixing step and provides a much larger surface area between phases, resulting in faster, more consistent extractions. The simplified workflow reduces hands-on time and minimizes analyst-to-analyst variability.

Advantages of Supported Liquid Extraction Using Synthetic Media

Traditional SLE uses natural diatomaceous earth, which can vary in particle size and structure, leading to inconsistent water-holding capacity and performance. To address these issues, Chem Elut S SLE from Agilent uses synthetic media that offer superior batch-to-batch consistency and reproducibility.

Key advantages include:

- Higher and more consistent water-holding capacity

- Uniform particle size and porosity for predictable flow

- Reduced risk of emulsion formation

- Compatibility with 96-well microplates for LCMS automation

The 96-well Chem Elut S design features a large headspace for sample and eluent, a full skirt for hardware compatibility, and a square upper frit that holds samples in place until positive pressure is applied—allowing fast, consistent elution into collection plates.

Key Differences Between LLE and SLE

| Feature | Liquid-Liquid Extraction (LLE) | Supported Liquid Extraction (SLE) |

|---|---|---|

| Workflow | Manual mixing and phase separation | Automated solvent flow through solid support |

| Labor Intensity | High; requires shaking, centrifugation | Low; minimal manual handling |

| Reproducibility | Operator-dependent | High consistency and reproducibility |

| Emulsion Formation | Common | Virtually eliminated |

| Automation Compatibility | Difficult to automate | Ideal for high-throughput LCMS workflows |

Conclusion

While both LLE and SLE are effective for analyte extraction, Supported Liquid Extraction offers a faster, cleaner, and more reproducible workflow. By eliminating shaking, centrifugation, and emulsion risk, SLE provides a true “walk-away” automation solution for modern analytical labs.

The Agilent Chem Elut S SLE products—available through Chrom Tech—deliver reliable, high-quality extractions with minimal method development. Pair your Chem Elut S plate with Chrom Tech’s 96-well microplates and LCMS-compatible accessories to optimize your workflow from start to finish.

Frequently Asked Questions

Is supported liquid extraction better than liquid-liquid extraction?

Yes, SLE provides faster extractions, higher reproducibility, and eliminates emulsions—making it better suited for automated and high-throughput workflows compared to traditional LLE.

Can SLE completely replace LLE in all applications?

While SLE is more efficient for most aqueous-organic extractions, LLE may still be used for specialized separations requiring custom solvent ratios or nonaqueous systems.

What makes Chem Elut S SLE media superior?

Chem Elut S uses synthetic media instead of diatomaceous earth, ensuring consistent pore size, enhanced water-holding capacity, and reproducible performance across batches.