Inlet Liners

Inlet Liners for Gas Chromatography

Agilent’s extensive portfolio of GC inlet liners, O-rings, and injector port seals is engineered to maintain a clean, inert, and precisely controlled environment during sample introduction. These components work together to ensure rapid, complete volatilization and reliable transfer of analytes onto the analytical column—one of the most critical steps in achieving accurate, reproducible chromatography.

The inlet liner plays a central role by isolating the sample flow path from the metal walls of the injector block, reducing unwanted interactions and preventing analyte loss. Differences in liner geometry—such as taper style, chamber design, or internal packing (e.g., glass wool)—directly influence vaporization efficiency, sensitivity, and discrimination. Selecting the right liner is essential to ensure all analytes vaporize uniformly before entering the column.

Agilent provides optimized liner designs for every major GC inlet configuration, including S/SL (Split/Splitless), MMI (Multimode), PTV (Programmed Temperature Vaporization), and HS (Headspace) systems. Whether your workflow demands high sensitivity, reduced matrix activity, or robust performance across varied sample types, Agilent’s inlet liners deliver consistent, high-quality results.

Agilent Ultra Inert Liners

| Image | Description | Volume (µL) | ID (mm) | EA | 5/pk | 25/pk | 100/pk* |

|---|---|---|---|---|---|---|---|

| SPLIT INLET LINERS | |||||||

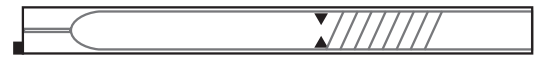

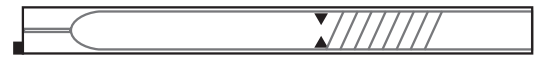

|

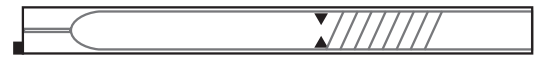

Low pressure drop, Ultra Inert liner w/ glass wool | 870 | 4 | 5190-2295 | 5190-3165 | 5190-3169 | 5190-3173 |

|

Straight, Ultra Inert liner with glass wool | 990 | 4 | 5190-2294 | 5190-3164 | 5190-3168 | 5190-3172 |

| SPLITLESS INLET LINERS | |||||||

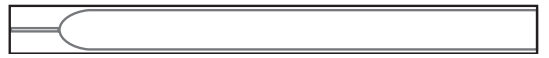

|

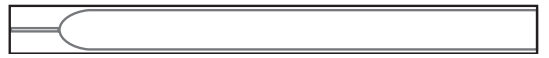

Single taper, Ultra Inert liner | 900 | 4 | 5190-2292 | 5190-3162 | 5190-3166 | 5190-3170 |

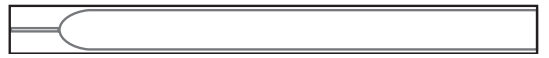

|

Single taper, Ultra Inert liner w/ glass wool | 900 | 4 | 5190-2293 | 5190-3163 | 5190-3167 | 5190-3171 |

|

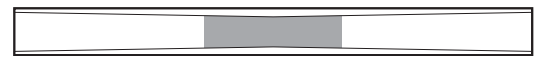

Splitless, double taper Ultra Inert liner (no wool) | 800 | 4 | 5190-3983 | 5190-4007 | — | — |

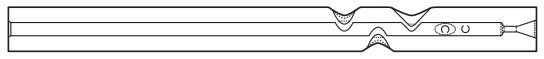

|

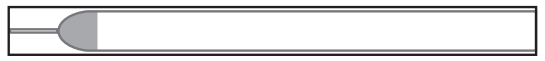

Dimpled, splitless, Ultra Inert liner | 200 | 2 | 5190-2297 | 5190-4006 | — | — |

|

Straight, Ultra Inert liner | 1 | 1 | 5190-4047 | — | — | — |

|

Straight Ultra Inert liner for SPME | 0.75 | — | 5190-4048 | — | — | — |

Agilent Original Deactivation Split & Splitless Liners

| Image | Description | Volume (µL) | ID (mm) | EA | 5/pk | 25/pk | 100/pk |

|---|---|---|---|---|---|---|---|

| SINGLE TAPER SPLIT LINERS | |||||||

|

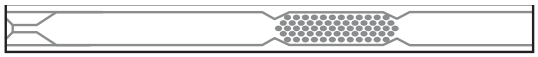

Single taper, glass wool, deactivated, low pressure drop | 870 | 4 | 5183-4647 | 5183-4701 | 5183-4702 | 5190-2275 |

|

Single taper, glass wool, deactivated | 870 | 4 | 5183-4711 | 5183-4712 | 5183-4713 | — |

| SINGLE TAPER SPLITLESS LINERS | |||||||

|

Single taper, deactivated | 900 | 4 | 5181-3316 | 5183-4695 | 5183-4696 | 5190-2270 |

|

Single taper, inert | 900 | 4 | 5181-3316i | — | — | — |

|

Single taper, glass wool, deactivated | 900 | 4 | 5062-3587 | 5183-4693 | 5183-4694 | 5190-2271 |

| STRAIGHT SPLIT LINERS | |||||||

|

Straight, glass wool, non-deactivated | 990 | 4 | 19251-60540 | 5183-4691 | 5183-4692 | — |

| STRAIGHT SPLITLESS LINERS | |||||||

|

Straight, deactivated, quartz | 250 | 2 | 5181-8818 | 5183-4703 | 5183-4704 | — |

|

Straight, non-deactivated, quartz | 250 | 2 | 18740-80220 | 5183-4707 | 5183-4708 | — |

|

Straight, non-deactivated | 990 | 4 | 210-3003 | 210-3003-5 | — | — |

| FOCUS SPLIT LINERS | |||||||

|

Deactivated with glass wool | 935 | 4 | — | 210-4004-5 | — | — |

|

Tapered, deactivated with glass wool | 880 | 4 | — | 210-4022-5 | — | — |

| DOUBLE TAPER SPLITLESS LINERS | |||||||

|

Double taper, deactivated | 800 | 4 | 5181-3315 | 5183-4705 | 5183-4706 | 5190-2272 |

| DIRECT INLET SPLITLESS LINERS | |||||||

|

Straight, non-deactivated (for gas samples, headspace, or purge & trap) | 140 | 1.5 | 18740-80200 | 5183-4709 | 5183-4710 | — |