Posted by Chrom Tech on 14th Oct 2025

Extra HPLC Pump Parts You Need To Have on Hand

Modern HPLC pumps are designed for long-term, reliable performance — often running 24 hours a day, 7 days a week, 365 days a year. To keep your system operating at peak efficiency, it’s essential to schedule regular maintenance and keep common replacement parts readily available in your lab.

Top 5 HPLC Pump Parts to Keep in Your Lab Drawer

- Inlet and Outlet Check Valves

- Piston Seals

- Replacement HPLC Fittings (low and high pressure)

- Inlet Solvent Filters

- Replacement HPLC Tubing (low- and high-pressure tubing)

"A well-maintained HPLC pump ensures consistent flow, accurate gradients, and minimal downtime."

1. HPLC Inlet and Outlet Check Valves

Check valves are critical for maintaining solvent flow direction and pump efficiency. Small particulates often cause check valve failures by interfering with valve operation. While cleaning may help temporarily, replacement is usually the best long-term solution.

If you notice erratic flow rates or no flow from the outlet check valve, replacing the check valve should be your first troubleshooting step. Chrom Tech carries both inlet and outlet check valves — including self-flush varieties — compatible with many Agilent and other OEM pump systems.

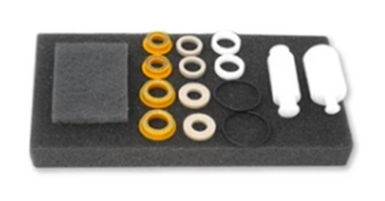

2. HPLC Piston Seals and Self-Flush Seals

Piston seals are responsible for maintaining pressure and preventing leaks inside the pump head. Symptoms of worn seals include pressure fluctuations, low system pressure, or visible leaks. Depending on solvent type and usage, seals typically need replacement every 1,000 hours of operation. Chrom Tech offers OEM and compatible piston seal kits to restore pump performance and reduce downtime.

3. Replacement HPLC Fittings

HPLC fittings are another common maintenance item that can affect system performance. Over-tightening or insufficient tightening can both cause leaks. PEEK fittings and tubing are particularly prone to wear over time. To prevent system leaks, it’s good practice to keep spare high- and low-pressure HPLC fittings on hand.

- Low-pressure fittings: ¼-28 flat-bottom (flangeless) style

- High-pressure fittings: 10-32 coned fittings, typically for 1/16” OD tubing

If you’re unsure which fitting style fits your pump, contact Chrom Tech’s technical team for guidance.

4. Inlet Solvent Filters

Many HPLC pump problems originate from particulates in the mobile phase. Installing an inlet solvent filter—sometimes called a “sinker”—in each solvent reservoir helps protect the pump’s internal components.

The filter holds the inlet tubing securely in place while removing particles that could damage piston seals or check valves. We recommend using 10 µm or 20 µm filters to balance filtration efficiency and solvent flow. Be sure to replace clogged filters regularly to avoid cavitation, which occurs when vapor bubbles form due to restricted flow.

5. Replacement HPLC Tubing

Crimped or clogged tubing can lead to pressure drops or flow inconsistencies. Replacing both inlet (low-pressure) and outlet (high-pressure) tubing as part of your preventative maintenance plan will help maintain stable flow and system performance.

Low-Pressure Inlet Tubing

Typically made from fluoropolymer (FEP) with a 1/8” OD and 1/16” ID, low-pressure inlet tubing is translucent—allowing you to monitor flow and detect air bubbles. Replace any tubing showing discoloration, kinks, or restriction.

High-Pressure Outlet Tubing

Downstream of the pump, high-pressure tubing must withstand system pressures and resist chemical corrosion. PEEK and stainless steel tubing are the most common materials used here. Because of their small inner diameters, these lines can clog easily and should be replaced periodically.

Chrom Tech stocks both PEEK tubing and stainless-steel tubing for same-day shipment to keep your lab running smoothly.

Conclusion

To maximize uptime and prevent unexpected downtime, keep essential HPLC pump parts—like seals, filters, fittings, and tubing—readily available in your lab. Regular preventative maintenance helps your pump operate at peak performance, ensuring consistent, accurate chromatography results. For assistance identifying the right replacement parts for your system, reach out to Chrom Tech Support.

Frequently Asked Questions About HPLC Pump Maintenance

How often should I replace my HPLC piston seals?

It’s recommended to replace piston seals approximately every 1,000 hours of run time, or sooner if you observe pressure fluctuations or leaks. Solvent type and pump design may affect this interval.

What causes check valve failure in HPLC pumps?

Check valve issues are often caused by particulate contamination. Using high-quality solvent filters and replacing worn valves ensures reliable flow and pressure stability.

How do I prevent cavitation in my HPLC pump?

Prevent cavitation by using clean solvents, maintaining unobstructed inlet tubing, and replacing clogged inlet solvent filters regularly. This prevents vapor bubble formation and ensures smooth solvent flow into the pump.