Posted by Chrom Tech on 2nd Feb 2026

Do You Really Need Helium as Your Carrier Gas?

The ongoing helium shortage has made it increasingly difficult for chromatographers to maintain consistent GC operations. Many laboratories are now receiving as little as 50% of their usual helium supply, leading to workflow interruptions, inflated costs, and delivery delays. To help mitigate these challenges, Chrom Tech offers alternative carrier gas solutions and gas generation systems designed to keep your GC analyses running smoothly, efficiently, and cost-effectively.

Do You Really Need Helium as Your Carrier Gas?

Helium has long been the industry standard for gas chromatography due to its inertness, efficiency, and compatibility with most established methods. However, not all GC applications require helium. Some methods—particularly regulated assays or GC/MS workflows requiring ultra-high sensitivity—must use helium for compliance or performance reasons. In these cases, the best approach is to conserve your helium supply by minimizing leaks, regularly checking system connections, and using optimized flow rates.

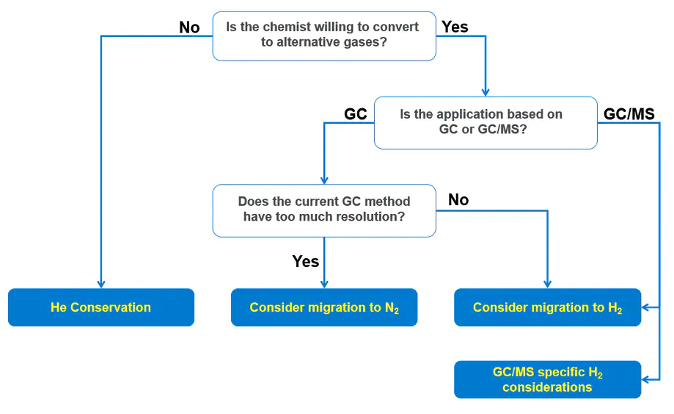

For other general-purpose GC methods, there is flexibility to switch to hydrogen or nitrogen as alternative carrier gases. The diagram below highlights factors to consider before making the transition:

Converting to an Alternative GC Carrier Gas

There are three primary carrier gases used in gas chromatography: helium, hydrogen, and nitrogen. Each has unique properties and trade-offs:

- Helium: The most common GC carrier gas, valued for its performance and inertness. However, its global scarcity results in rising prices and unreliable supply chains.

- Hydrogen: The most effective helium alternative for GC and GC/MS. It provides fast analysis times and comparable resolution with minimal method modification. However, hydrogen is flammable and requires proper safeguards.

- Nitrogen: A cost-effective and readily available option, though it often produces longer run times and is not recommended for GC/MS applications due to reduced sensitivity.

For GC/MS workflows, hydrogen is generally the preferred substitute. For standard GC analyses that do not demand maximum resolution, nitrogen can serve as a practical and economical choice. Modern method translation software can assist with recalibrating retention times and optimizing parameters when transitioning from helium to another gas type.

Benefits of Hydrogen or Nitrogen Gas Generators

Once your lab has identified a suitable carrier gas alternative, consider the benefits of using a gas generator instead of traditional gas cylinders. These compact systems produce ultra-pure hydrogen or nitrogen on demand, eliminating logistical challenges and improving safety. Chrom Tech offers both hydrogen generators and nitrogen generators for analytical laboratories.

Key advantages of gas generators include:

- Safety: Gas is generated on demand, minimizing the risk of storing large volumes of flammable gases or handling heavy cylinders.

- Cost Savings: Eliminates recurring cylinder rental, delivery, and replacement fees—eventually paying for itself over time.

- Convenience: No manual gas monitoring or cylinder changes required; continuous, consistent gas purity is maintained.

- Space Efficiency: Compact design saves valuable laboratory floor space.

By investing in a gas generator, your lab gains cost stability, independence from helium shortages, and consistent supply without relying on external distributors. It’s a long-term solution that enhances safety, reduces downtime, and provides peace of mind for chromatographers managing critical analyses.

Chrom Tech: Supporting GC Labs Through Helium Shortages

Chrom Tech is your comprehensive partner for gas chromatography consumables and instrumentation. Whether you need GC vials, columns, fittings, or accessories, our experts can help identify the best products to optimize your gas usage and maintain analytical performance despite helium constraints.

Explore our full GC product line or contact a Chrom Tech specialist for personalized guidance on transitioning to alternative carrier gases and gas generation solutions.

Frequently Asked Questions About Helium Alternatives

Can I replace helium with hydrogen in my GC/MS system?

Yes. Hydrogen is the best helium alternative for GC/MS applications because it maintains fast analysis speeds and high resolution. However, safety precautions must be taken since hydrogen is flammable. Many GC systems include built-in safeguards to accommodate hydrogen use safely.

When should I use nitrogen as a carrier gas?

Nitrogen is an economical choice for general GC applications where analysis time is less critical and ultra-high resolution is not required. However, it’s unsuitable for GC/MS due to lower sensitivity and longer run times.

What are the advantages of using a gas generator?

Gas generators produce hydrogen or nitrogen on demand, eliminating the need for gas cylinders. They improve safety, reduce costs over time, and ensure consistent gas purity for uninterrupted GC operation.

Where can I find GC consumables to support carrier gas changes?

Chrom Tech provides a wide range of GC supplies—including columns, fittings, and GC vials—as well as expert guidance for optimizing your system’s performance when switching carrier gases.