Back Pressure Regulators (BPRs)

IDEX Back Pressure Regulators (BPRs) are designed to improve chromatographic system performance by maintaining consistent downstream pressure, helping prevent outgassing and enhancing pump check valve efficiency. These regulators are commonly used in HPLC, UHPLC, LC-MS, and multi-detector workflows where stable pressure control is essential for accurate, reproducible results.

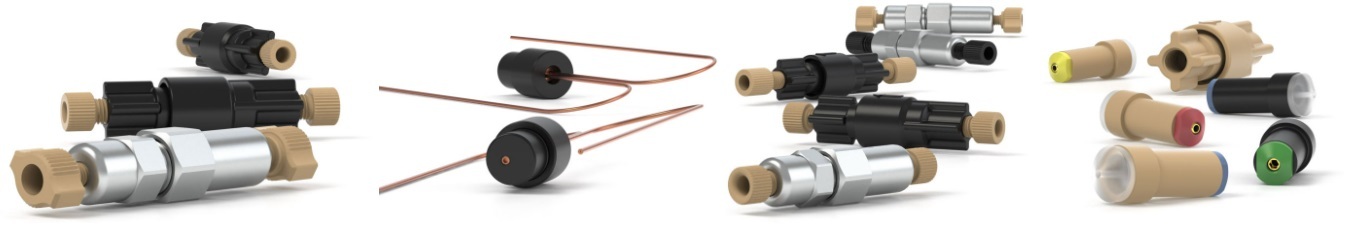

Chrom Tech offers a complete selection of BPR assemblies, cartridges, holders, adjustable high-pressure regulators, and ultra-low volume BPRs. Available configurations include fixed-pressure assemblies at 5 and 20 psi, factory-preset cartridges and assemblies spanning 40 to 1,000 psi (2.8 to 69 bar), and high-pressure adjustable BPRs supporting operating ranges between 2,000 and 5,000 psi. Ultra-low volume models—set to 100 or 500 psi—feature swept volumes as low as 6 µL, making them ideal for sensitive multi-detector and low-dispersion applications.

BPR Assemblies are available in both biocompatible and stainless steel configurations. Biocompatible assemblies utilize a PEEK holder, polymer fittings, and chemically resistant cartridges, while stainless steel assemblies combine the same biocompatible cartridges with a 316 stainless steel holder for added durability. Each assembly includes a factory preset cartridge (except 5 and 20 psi versions) and is designed to deliver consistent incremental back pressure across typical analytical flow rates.

BPR Cartridges are manufactured from PEEK, Tefzel® (ETFE), perfluoroelastomer, and gold-plated stainless steel for broad chemical compatibility. These replacement cartridges operate across recommended flow rates of 0.1–10 mL/min, maintaining pressure stability within ±10% under normal conditions. They are fully interchangeable with standard IDEX BPR holders, allowing flexible system configuration and easy pressure adjustments.

Back Pressure Regulator Holders accept any compatible replacement cartridge and ship with fittings for 1/16" OD tubing. Select holders are surface-treated to prevent galling, ensuring smooth operation during installation. For optimal performance, cartridges are designed to reach their rated pressure when tightened to approximately 20 in-lbs of torque, which can be achieved by finger tightening followed by an additional 1/8–1/4 turn using the supplied wrenches.

Whether you need precise low-pressure control, ultra-low swept volume for detector-sensitive applications, or high-pressure regulation for demanding LC workflows, Chrom Tech provides a full range of IDEX Back Pressure Regulators and accessories—many stocked and ready to ship.

Back Pressure Assemblies

| Part No | Pressure Setting | Holder Material | Includes | Swept Volume |

|---|---|---|---|---|

| P-790 | 5 PSI | PEEK | (2) XP-215 | 134 µL |

| P-791 | 20 PSI | PEEK | (2) XP-215 | 134 µL |

| P-785 | 40 PSI | PEEK | (1) P-761, (2) XP-215 | 131 µL |

| P-786 | 75 PSI | PEEK | (1) P-762, (2) XP-215 | 131 µL |

| P-787 | 100 PSI | PEEK | (1) P-763, (2) XP-215 | 131 µL |

| P-788 | 250 PSI | PEEK | (1) P-764, (2) XP-235 | 102 µL |

| P-789 | 500 PSI | PEEK | (1) P-765, (2) P-250, (2) LT-115 | 96 µL |

| P-455 | 1,000 PSI | PEEK | (1) P-796, (2) P-250, (2) LT-115 | 89 µL |

| U-605 | 40 PSI | SST | (1) P-761, (2) XP-201 | 129 µL |

| U-606 | 75 PSI | SST | (1) P-762, (2) XP-201 | 129 µL |

| U-607 | 100 PSI | SST | (1) P-763, (2) XP-201 | 129 µL |

| U-608 | 250 PSI | SST | (1) P-764, (2) XP-201 | 99 µL |

| U-609 | 500 PSI | SST | (1) P-765, (2) XP-201 | 93 µL |

| U-610 | 750 PSI | SST | (1) P-795, (2) P-250, (2) LT-115 | 91 µL |

| HIGH PRESSURE ADJUSTABLE BPR ASSEMBLY | ||||

| P-880 | 2,000–5,000 PSI | — | (2) F-120BLK | 9 µL |