Application Specific

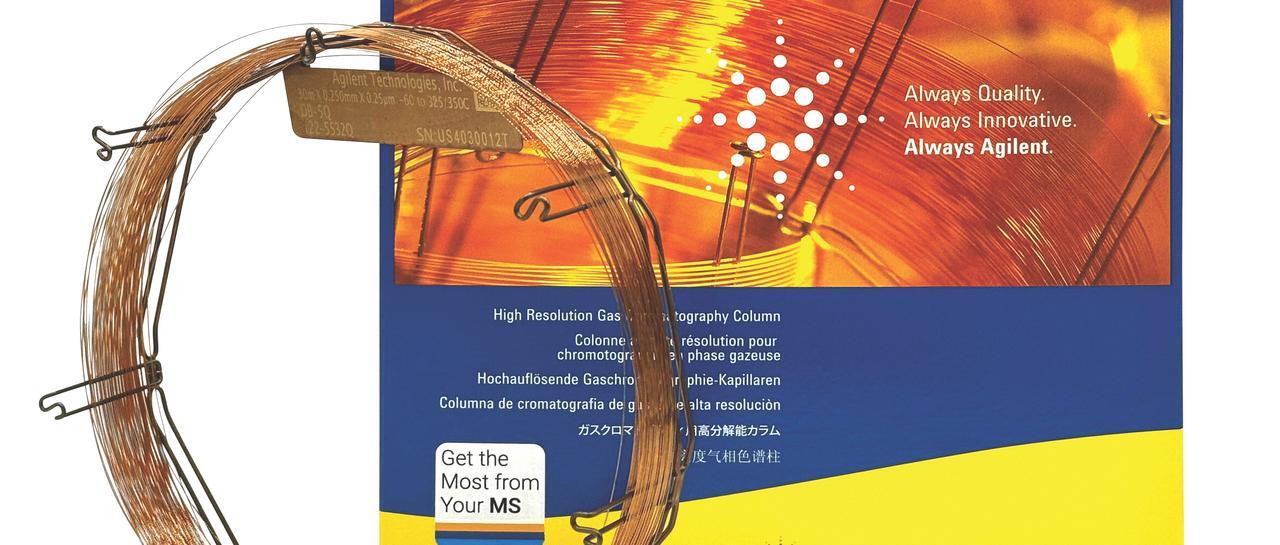

Agilent Metal GC Columns — Application Specific

Agilent Application Specific Metal GC Columns are engineered to deliver robust, high-precision

performance for specialized workflows where standard fused-silica columns may not provide the required

durability, selectivity, or operational stability. Built using rugged stainless-steel or metal-clad

tubing, these columns withstand demanding conditions—including high temperatures, elevated inlet

pressures, repeated handling, and process-GC environments—while providing reliable, reproducible

chromatographic results tailored to each application.

Each column in this category features a stationary phase and design optimized for a defined analytical purpose. Examples include columns such as CP7463, engineered for high-temperature analysis and refinery-grade process monitoring, and 145-1334, configured for precise separations in industrial gas analysis workflows. These application-focused columns offer rugged stability, excellent retention-time reproducibility, and the selectivity required to meet method-specific performance specifications in petrochemical, environmental, chemical-manufacturing, and specialty-gas laboratories.

Agilent’s metal construction minimizes breakage risk, simplifies installation in compact or high-vibration systems, and enables stable operation under extreme conditions where fused-silica columns experience shortened lifetimes. By combining method-matched selectivity with the enhanced durability of metal tubing, Agilent Application Specific Metal GC Columns provide laboratories with a dependable solution for consistent, long-term analysis in even the harshest operating environments.

Each column in this category features a stationary phase and design optimized for a defined analytical purpose. Examples include columns such as CP7463, engineered for high-temperature analysis and refinery-grade process monitoring, and 145-1334, configured for precise separations in industrial gas analysis workflows. These application-focused columns offer rugged stability, excellent retention-time reproducibility, and the selectivity required to meet method-specific performance specifications in petrochemical, environmental, chemical-manufacturing, and specialty-gas laboratories.

Agilent’s metal construction minimizes breakage risk, simplifies installation in compact or high-vibration systems, and enables stable operation under extreme conditions where fused-silica columns experience shortened lifetimes. By combining method-matched selectivity with the enhanced durability of metal tubing, Agilent Application Specific Metal GC Columns provide laboratories with a dependable solution for consistent, long-term analysis in even the harshest operating environments.