Agilent Capillaries

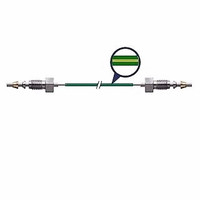

Agilent HPLC capillaries are precision-engineered for use in the high-pressure flow path of liquid chromatography systems, providing reliable connections between LC modules and columns. Each capillary is manufactured to exact Agilent specifications to ensure optimal system fit and help preserve chromatographic performance across your entire LC workflow.

Agilent’s proprietary laser welding process produces perfectly flat capillary ends, virtually eliminating capillary-induced dead volume and supporting accurate, reproducible results. This precision construction helps maintain peak integrity while minimizing dispersion at critical connection points.

Available in a range of materials to support diverse applications, Agilent HPLC capillaries include stainless steel for durability and flexibility in standard analyses, as well as MP35N, PEEK-lined stainless steel, and titanium options for enhanced inertness and corrosion resistance in bio and sensitive workflows.

All Agilent HPLC capillary tubing is color-coded by inner diameter, allowing quick visual identification during installation and maintenance while helping reduce connection errors in complex systems.

Application Highlights

• High-pressure LC flow path connections

• Module-to-column and inter-module plumbing

• Standard and bio-inert chromatography workflows

• Low-dead-volume system optimization

Chrom Tech stocks a broad selection of Agilent HPLC capillaries in multiple materials, lengths, and inner diameters to support routine HPLC, UHPLC, and bio-LC applications, with many common configurations available for fast shipment.